-

Automatic Packing and Palletizing Line was Shipped to The United Arab Emirates

Time: On July 4, 2025.

Location: The United Arab Emirates.

Event: On July 4, 2025. CORINMAC's automatic packing and palletizing line equipment was successfully loaded and shipped to The United Arab Emirates.

The whole set of automatic packing and palletizing line equipment including valve bag packing machine, automatic palletizing robot, ton bag packing machine, dust collecting press conveyor, inkjet printer, finished product hopper, belt conveyor, impulse bags dust collector, electric control cabinet, and spare parts, etc.

Container loading photos are as follows:

-

Valve Bag Packing Machine Was Delivered to Armenia

Time: On July 1st, 2025.

Location: Armenia.

Event: On July 1st, 2025. CORINMAC's valve bag packing machine, dust collector, air compressor, valve and spare parts were successfully loaded and delivered to Armenia.

The valve bag packing (filling) machine is designed to fill valve-type bags with various bulk products. It can be used for packing dry building mixes, cement, gypsum, dry paints, flour and other materials.

Container loading photos are as follows:

-

Dry Mortar Production Line and Sand Drying Production Line were Delivered to Lebanon

Time: On June 22, 2025.

Location: Lebanon.

Event: On June 22, 2025. CORINMAC's dry mortar production line and sand drying production line were successfully loaded and delivered to Lebanon.

The whole set of dry mortar production line and sand drying production line equipment including weighing hopper, finished product hopper, ton bag un-loader, impeller packing machine for valve bag, open mouth bag packing machine, small bag packing machine, spiral ribbon mixer, single shaft paddle mixer, screw conveyor, wet sand hopper, belt conveyor, burning chamber, three cylinder rotary dryer, cyclone dust collector, exhaust fan, vibrating screen, control cabinet and spare parts, etc.

Container loading photos are as follows:

-

Refractory Crushing and Screening Equipment was Shipped to Uzbekistan

Time: From June 11, 2025 to June 12, 2025.

Location: Uzbekistan.

Event: From June 11, 2025 to June 12, 2025. CORINMAC's refractory crushing and screening line was successfully loaded and shipped to Uzbekistan.

The whole set of refractory crushing and screening line equipment including jaw crusher, hammer crusher, vibrating screen, impulse bags dust collector, bucket elevator, belt conveyor, raw material hopper, ton bag packing machine, pallet wrapping machine, control cabinet and spare parts, etc.

Container loading photos are as follows:

-

Dry Mortar Production Line was Delivered to Qatar

Time: On June 8, 2025.

Location: Qatar.

Event: On June 8, 2025. CORINMAC's dry mortar production line was delivered to Qatar.

The whole set of dry mortar production line equipment including weighing hopper, single shaft mixer, jumbo bag un-loader, screw conveyor, finished product hopper, belt conveyor, packing machine, control cabinet and spare parts, etc.

CORINMAC is a professional manufacturer of dry mortar production equipment, and we provide customized dry mortar production plant and solutions according to different site conditions of users. There are simple, vertical, and tower type production lines for users to choose from, with a wide range of output. The dry mortar production line has a high degree of automation, good stability, no dust, and the finished mortar is highly competitive.

Container loading photos are as follows:

-

Dry Mortar Production Line and Texture Paint Mixing Line were Shipped to Albania

Time: From June 3, 2025 to June 6, 2025.

Location: Albania.

Event: From June 3, 2025 to June 6, 2025. CORINMAC's dry mortar production line and texture paint mixing line equipment were shipped to Albania.

The whole set of dry mortar production line and texture paint mixing line equipment including weighing hopper, bucket elevator, single shaft mixer, impulse bags dust collector, jumbo bag un-loader, screw conveyor, finished product hopper, steel structure, packing machine, texture paint mixer, control cabinet and spare parts, etc.

Container loading photos are as follows:

-

Automatic Packing and Palletizing Line and Additives Weighing System were Shipped to Kyrgyzstan

Time: May 30, 2025.

Location: Kyrgyzstan.

Event: On May 30, 2025. CORINMAC's automatic packing and palletizing line, additives weighing system and impulse bags dust collector were shipped to Kyrgyzstan.

The whole set of automatic packing and palletizing line equipment including automatic bag placer for packing machine, automatic valve bag packing machine, belt conveyor, dust collecting press conveyor, automatic palletizing robot, inkjet printer, automatic pallet feeder, control cabinet, and spare parts, etc.

Container loading photos are as follows:

-

Column Palletizer was Delivered to Russia

Time: May 28, 2025.

Location: Russia.

Event: On May 28, 2025, CORINMAC’s column palletizer was delivered to Russia. Palletizing equipment including column palletizer, dust collecting press conveyor, pickup conveyor, control cabinet and spare parts, etc.

Column palletizer can also be called Rotary palletizer, Single Column palletizer, or Coordinate palletizer, it is the most concise and compact type of palletizer. The Column Palletizer can handle bags containing stable, aerated or powdery products, permitting partial overlapping of the bags in the layer along both the top and sides, offering flexible format changes. Its extreme simplicity makes it possible to palletise even on pallets sitting directly on the floor.

Delivery photos are as follows:

-

Weighing and Screening Equipment were Delivered to Malaysia

Time: May 12, 2025.

Location: Malaysia.

Event: On May 12, 2025, CORINMAC’s weighing and screening equipment were delivered to Malaysia. The equipment including vibrating screen, screw conveyor, weighing hopper, and spare parts, etc.

If the raw material such as sand requires a specific particle size, a Vibrating screen is needed to screen the raw sand and control its size. Without special requirements, we are equipped with a linear vibration type screening machine in the production line. The linear vibratory screening machine has the advantages of simple structure, energy saving and high efficiency, small area cover and low maintenance cost. It is an ideal equipment for dry sand screening.

The weighing hopper consists of hopper, steel frame, and load cell (the lower part of the weighing hopper is equipped with a discharge screw conveyor). The weighing hopper is widely used in various dry mortar production lines to weigh ingredients such as cement, sand, fly ash, light calcium, and heavy calcium. It has the advantages of fast batching speed, high measurement accuracy, strong versatility, and could handle various bulk materials.

-

Bucket Elevator and Belt Conveyor were Shipped to Kazakhstan

Time: April 30, 2025.

Location: Kazakhstan.

Event: On April 30, 2025, CORINMAC’s bucket elevator and belt conveyor were shipped to Kazakhstan.

Bucket elevator is a widely used vertical conveying equipment. It is used for vertical conveying of powder, granular and bulk materials, as well as highly abrasive materials, such as cement, sand, soil coal, sand, etc. The material temperature is generally below 250 °C, and the lifting height can reach 50 meters. Conveying capacity: 10-450m³/h. Widely used in building materials, electric power, metallurgy, machinery, chemical industry, mining and other industries.

Container loading photos are as follows:

-

CORINMAC Wishes You a Happy Labor Day

May 1st is International Workers' Day. CORINMAC wishes you a happy Labor Day! In celebration of International Workers' Day (May 1st), CORINMAC will observe the holiday as follows:

Holiday Period:

May 1st (Thursday) – May 5th (Monday), 2025

Normal operations resume: May 6th, 2025(Tuesday).During this time:

All production and shipments will pause temporarily.

Customer service will respond to urgent inquiries via email: corin@corinmac.com.

For emergency technical support, contact: +8615639922550.We appreciate your understanding and wish everyone a safe and happy holiday! Thank you for your continued trust in CORINMAC mortar equipment.

CORINMAC is grateful to have you along the way. May our efficient mortar equipment continue to empower your projects, saving your time and effort. Win-win cooperation, a promising future ahead!

-

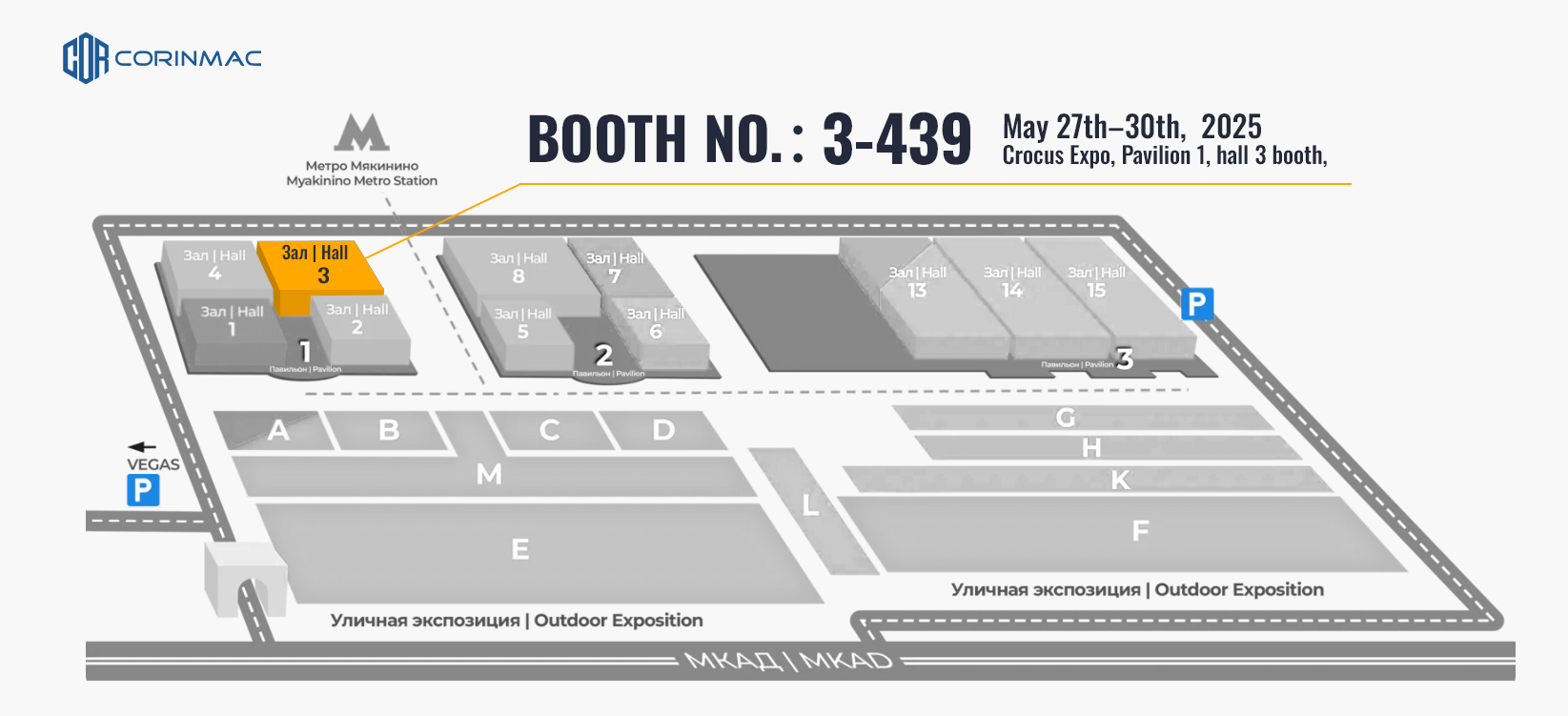

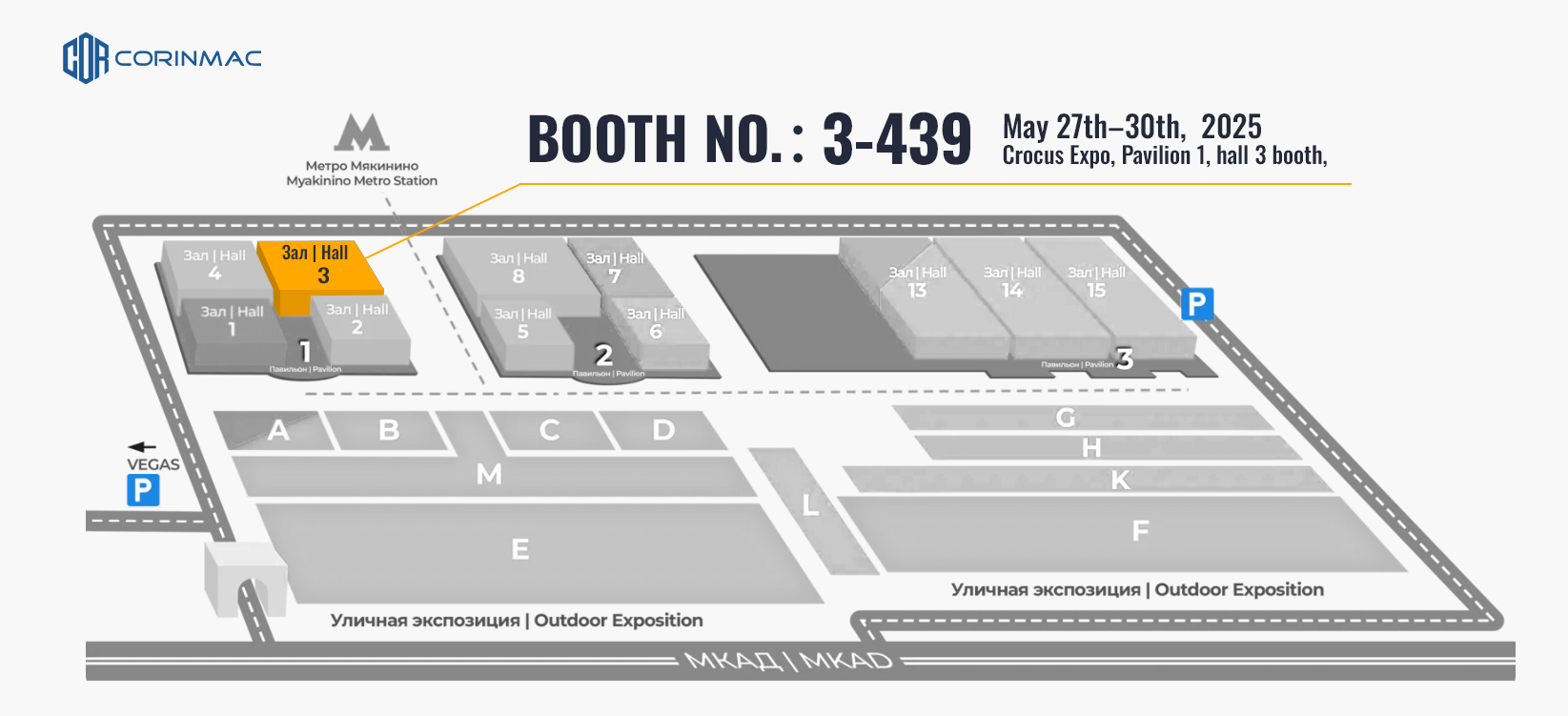

CORINMAC Will Participate in CTT EXPO 2025 Exhibition in Moscow

Time: From May 27 to 30, 2025.

Location: Moscow, Russia.

Event: CORINMAC will participate in CTT EXPO 2025 exhibition held in Moscow, Russia from May 27 to 30, 2025. We invite all friends to visit our booth to view and discuss. Whether new friends who are interested in our equipment or old friends who have already bought equipment from us, we sincerely welcome your arrival!

Our booth is located in Crocus Expo, Pavilion 1, Hall 3, booth number: 3-439.

ZHENGZHOU CORIN MACHINERY CO.,LTD sincerely welcome friends to our booth to view and discuss! Looking forward to meeting you in Moscow!