Vibrating screen with high screening efficiency and stable operation

Product Detail

Vibrating screen introduction

The dry sand screening machine can be divided into three types: linear vibration type, cylindrical type and swing type. Without special requirements, we are equipped with a linear vibration type screening machine in this production line. The screen box of the screening machine has a fully sealed structure, which effectively reduces the dust generated during the working process. Sieve box side plates, power transmission plates and other components are high-quality alloy steel plates, with high yield strength and long service life. The exciting force of this machine is provided by a new type of special vibration motor. The exciting force can be adjusted by adjusting the eccentric block. The number of layers of the screen can be set to 1-3, and a stretch ball is installed between the screens of each layer to prevent the screen from clogging and improve the screening efficiency. The linear vibratory screening machine has the advantages of simple structure, energy saving and high efficiency, small area cover and low maintenance cost. It is an ideal equipment for dry sand screening.

Working principle

The material enters the sieve box through the feeding port, and is driven by two vibrating motors to generate the exciting force to throw the material upward. At the same time, it moves forward in a straight line, and screens a variety of materials with different particle sizes through a multilayer screen, and discharge from the respective outlet. The machine has the characteristics of simple structure, energy saving and high efficiency, and fully enclosed structure without dust overflow.

After drying, the finished sand (water content is generally below 0.5%) enters the vibrating screen, which can be sieved into different particle sizes and discharged from the respective discharge ports according to the requirements. Usually, the size of the screen mesh is 0.63mm, 1.2mm and 2.0mm, the specific mesh size is selected and determined according to actual needs.

All-steel screen frame, unique screen reinforcement technology, easy to replace the screen.

Contains rubber elastic balls, which can automatically clear the screen blockage.

Installation steps guidance

Drawing

Our products

Recommended products

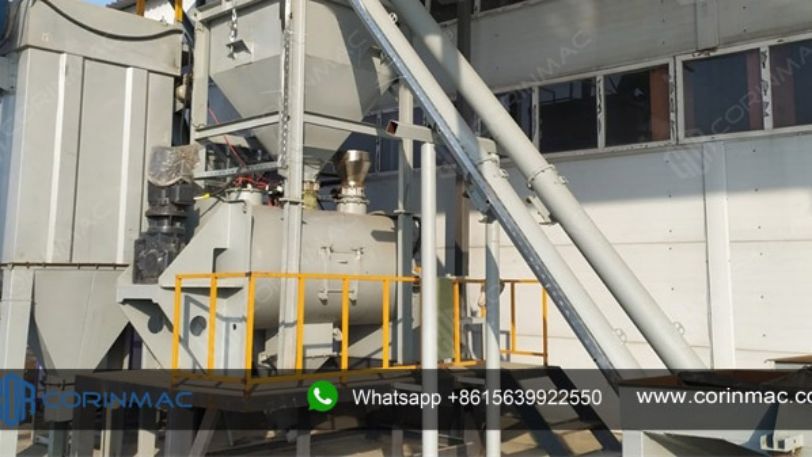

Vertical dry mortar production line CRL-HS

Capacity: 5-10TPH; 10-15TPH; 15-20TPH

see more

Tower type dry mortar production line

Capacity: 10-15TPH; 15-20TPH; 20-30TPH; 30-40TPH; 50-60TPH

Features and Advantages:

1. Low energy consumption and high production efficiency.

2. Less waste of raw materials, no dust pollution, and low failure rate.

3. And because of the structure of the raw material silos, the production line occupies 1/3 area of the flat production line.

Vertical dry mortar production line CRL-3

Capacity: 5-10TPH; 10-15TPH; 15-20TPH

see more

Dry mortar production line intelligent control ...

Features:

1. Multi-language operating system, English, Russian, Spanish, etc. can be customized according to customer requirements.

2. Visual operation interface.

3. Fully automatic intelligent control.

Simple dry mortar production line CRM2

Capacity: 1-3TPH; 3-5TPH; 5-10TPH

Features and Advantages:

1. Compact structure, small footprint.

2. Equipped with a ton bag unloading machine to process raw materials and reduce the work intensity of workers.

3. Use the weighing hopper to automatically batch ingredients to improve production efficiency.

4. The whole line can realize automatic control.

Screw conveyor with unique sealing technology

Features:

1. The external bearing is adopted to prevent dust from entering and prolong the service life.

2. High quality reducer, stable and reliable.

see more