Vertical dry mortar production line CRL-H

Product Detail

Introduction

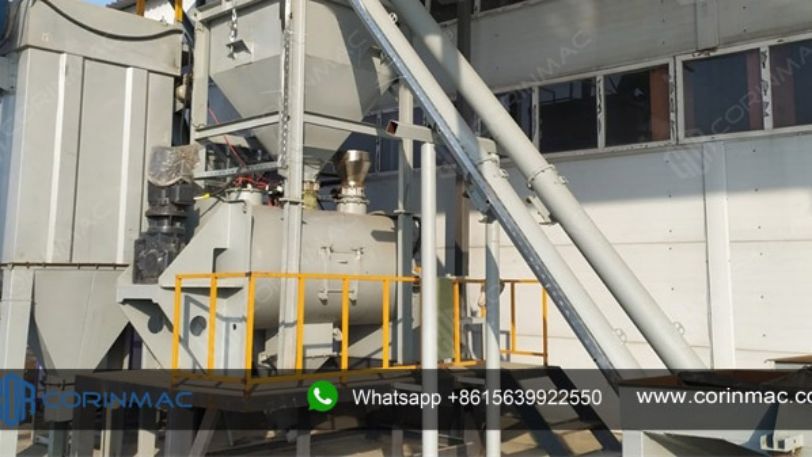

Vertical dry mortar production line

Vertical mortar production line CRL-H series is a combined production line of sand drying and standard mortar production (single line). The raw sand is processed into finished sand by a dryer and a vibrating screen, and then the finished sand, cementitious materials (cement, gypsum, etc.), various additives and other raw materials according to a specific recipe, mix with a mixer, and mechanically packing the obtained dry powder mortar, including raw material storage silo, screw conveyor, weighing hopper, additive batching system, bucket elevator, pre-mixed hopper, mixer, packaging machine, dust collectors and control system.

The name of the vertical mortar production line comes from its vertical structure. The pre-mixed hopper, the additive batching system, the mixer and the packaging machine are arranged on the steel structure platform from top to bottom, which can be divided into single-floor or multi-floors structure.

Mortar production lines will vary greatly due to differences in capacity requirements, technical performance, equipment composition and degree of automation. The entire production line scheme can be customized according to the customer's site and budget.

CRL-H series production line includes

-Drying and screening part

•Wet sand hopper

•Belt feeder

•Conveyors

•Rotary dryer

•Vibrating screen

•Dust collector and Auxiliary equipment

-Dry mortar production part

• Raw material lifting and conveying equipment;

• Raw material storage equipment (silo and ton bag un-loader)

• Batching and weighing system (main materials and additives)

• Mixer and packaging machine

• Control System

• Auxiliary equipment

Drying and screening part

Wet sand hopper

The wet sand hopper is used to receive and store the wet sand to be dried. The volume (standard capacity is 5T) can be customized according to user needs. The outlet at the bottom of the sand hopper is connected to a belt feeder. The structure is compact and reasonable, strong and durable.

Belt feeder

The belt feeder is the key equipment for evenly feeding the wet sand into the dryer, and the drying effect can be guaranteed only by feeding the material evenly. The feeder is equipped with a variable frequency speed regulating motor, and the feeding speed can be adjusted arbitrarily to achieve the best drying effect. It adopts skirt conveyor belt to prevent material leakage.

Three cylinder rotary dryer

The three cylinder rotary dryer is an efficient and energy-saving product improved on the basis of the single-cylinder rotary dryer.

There is a three-layer drum structure in the cylinder, which can make the material reciprocate three times in the cylinder, so that it can obtain sufficient heat exchange, greatly improve the heat utilization rate and reduce power consumption.

Vibrating screen

After drying, the finished sand (water content is generally below 0.5%) enters the vibrating screen, which can be sieved into different particle sizes and discharged from the respective discharge ports according to the requirements. Usually, the size of the screen mesh is 0.63mm, 1.2mm and 2.0mm, the specific mesh size is selected and determined according to actual needs.

Dust collector and Auxiliary equipment

Cyclone

It is connected to the air outlet of the dryer end cover through a pipeline, and is also the first dust removal device for the hot flue gas inside the dryer. There are a variety of structures such as single cyclone and double cyclone group could be chosen.

Impulse dust collector

It is another dust removal equipment in the drying line. Its internal multi-group filter bag structure and pulse jet design can effectively filter and collect dust in the dust-laden air, so that the dust content of the exhaust air is less than 50mg/m³, ensuring that it meets the environmental protection requirements. According to the needs, we have dozens of models such as DMC32, DMC64, DMC112 for selection.

Dry mortar production part

Lifting and Conveying equipment

Bucket elevator

The bucket elevator is designed for continuous vertical transportation of bulk materials such as sand, gravel, crushed stone, peat, slag, coal, etc. in the production of building materials, chemical, metallurgical and other industries.

Ton bag un-loader

A vibrating screen is used to sieve the sand into the desired particle size. The screen body adopts a fully sealed structure, which can effectively reduce the dust generated during the working process. Screen body side plates, power transmission plates and other components are made of high-quality alloy steel plates, with high yield strength and long service life.

Screw conveyor

Screw conveyor is suitable for conveying of non-viscous materials such as dry powder, cement, etc. It is used to transport dry powder, cement, gypsum powder and other raw materials to the mixer of the production line, and transport the mixed products to the finished product hopper. The lower end of the screw conveyor provided by our company is equipped with a feeding hopper, and the workers put the raw materials into the hopper. The screw is made of alloy steel plate, and the thickness is corresponding to the different materials to be conveyed. Both ends of the conveyor shaft adopt a special sealing structure to reduce the impact of dust on the bearing.

Raw material storage equipment (silo and ton bag un-loader)

Silo for cement, sand, lime, etc.

The silo (demountable design) is designed to receive cement from a cement truck, store it and deliver it along a screw conveyor to the batching system.

Loading of cement into the silo is carried out via a pneumatic cement pipeline. To prevent material hanging and ensure uninterrupted unloading, an aeration system is installed in the lower (cone) part of the silo.

Ton bag un-loader

As standard, the hopper is equipped with a breaker for ripping open soft containers of the "big-bag" type, a butterfly valve designed to fully open, close and regulate the flow of bulk materials from the hopper. at the request of the client, an electromechanical vibrator can be installed on the hopper to stimulate the unloading of bulk material.

• Batching and weighing system (main materials and additives)

Main materials weighing hopper

The weighing hopper consists of hopper, steel frame, and load cell (the lower part of the weighing hopper is equipped with a discharge screw). The weighing hopper is widely used in various mortar lines to weigh ingredients such as cement, sand, fly ash, light calcium, and heavy calcium. It has the advantages of fast batching speed, high measurement accuracy, strong versatility, and can handle various bulk materials.

Additives batching system

Mixer and packaging machine

Dry mortar mixer

The dry mortar mixer is the core equipment of the dry mortar production line, which determines the quality of the mortars. Different mortar mixers can be used according to different types of mortar.

Single shaft plough share mixer

The technology of the plough share mixer is mainly from Germany, and it is a mixer commonly used in large-scale dry powder mortar production lines. The plough share mixer is mainly composed of an outer cylinder, a main shaft, plough shares, and plough share handles. The rotation of the main shaft drives the plowshare-like blades to rotate at a high speed to drive the material to move rapidly in both directions, so as to achieve the purpose of mixing. The stirring speed is fast, and a flying knife is installed on the wall of the cylinder, which can quickly disperse the material, so that the mixing is more uniform and fast, and the mixing quality is high.

Single shaft plough share mixer (small discharge door)

Single shaft plough share mixer (big discharge door)

Single shaft plough share mixer (Supper high speed)

Product hopper

The finished product hopper is a closed silo made of alloy steel plates for storing mixed products. The top of the silo is equipped with a feeding port, a breathing system and a dust collection device. The cone part of the silo is equipped with a pneumatic vibrator and an arch breaking device to prevent the material from being blocked in the hopper.

Valve bag packing machine

According to the requirements of different customers, we can provide three different types of packing machine, impeller type, air blowing type and air floating type for your choice. The weighing module is the core part of the valve bag packing machine. The weighing sensor, weighing controller and electronic control components used in our packaging machine are all first-class brands, with large measuring range, high precision, sensitive feedback, and the weighing error could be ±0.2 %, can fully meet your requirements.

Control cabinet

The equipment listed above is the basic type of this type of production line.

If it is necessary to reduce dust in the workplace and improve the working environment of workers, a small pulse dust collector can be installed.

In short, we can do different program designs and configurations according to your requirements.

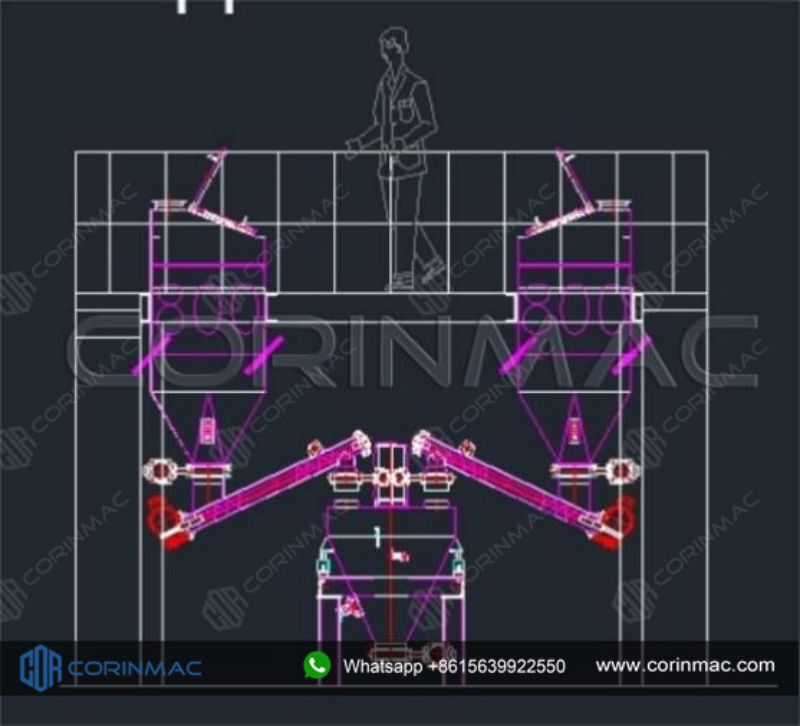

Installation steps guidance

Drawing

Certificates

We specialize in design, manufacture and supply the following products:

Dry mortar production line

Including Tile adhesive production line, Wall putty production line, Skim coat production line, Cement-based mortar production line, Gypsum-based mortar production line, and various types of dry mortar complete set of equipment. The product range includes Raw material storage silo, Batching & Weighing system, Mixers, Packing machine (Filling machine), Palletizing robot and PLC automatic control systems.

Dry mortar's raw mateiral production equipment

Including Rotary dryer, Sand drying production line, Grinding mill, Grinding produciton line for preparing gypsum, limestone, lime, marble and other stone powders.

What can we do for you?

We will provide each customer with customized production solutions to meet the requirements of different construction sites, workshops and production equipment layouts. We have a wealth of case sites in more than 40 countries around the world. The solutions designed for you will be flexible and efficient, and you will definitely get the most suitable production solutions from us!

Since its establishment in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers, providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer success is our success!

What can we do for you?

We will provide each customer with customized production solutions to meet the requirements of different construction sites, workshops and production equipment layouts. We have a wealth of case sites in more than 40 countries around the world. The solutions designed for you will be flexible and efficient, and you will definitely get the most suitable production solutions from us!

Since its establishment in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers, providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer success is our success!

Our Team

Overseas Markets

Oleg - Department head

Liu xinshi - Chief technical engineer

Lucy - Head of the Russian area

Irina - Russian sales manager

Kevin – Head of English area

Richard - English sales manager

Angel - English sales manager

Wang Ruidong - Mechanical engineer

Li Zhongrui – Process design engineer

Guanghui shi - Electrical engineer

Zhao Shitao - After-sales installation engineer

Overseas Markets

Георгий - Russian technical engineer

Артем - Russian Logistics Management

Шарлотта - Russian Documentation and Customs Clearance Services

Дархан - Kazakhstan technical engineer

Our products

Recommended products

Efficient and non-polluting Raymond Mill

Pressurizing device with high pressure spring can improve the grinding pressure of roller, which makes efficiency improved by 10%-20%. And the sealing performance and dust removal effect is pretty good.

Capacity: 0,5-3TPH; 2.1-5.6 TPH; 2.5-9.5 TPH; 6-13 TPH; 13-22 TPH.

Applications: Cement, Coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

see more

Splicable and stable sheet silo

Features:

1. The diameter of the silo body can be arbitrarily designed according to the needs.

2. Large storage capacity, generally 100-500 tons.

3. The silo body can be disassembled for transportation and assembled on site. Shipping costs are greatly reduced, and one container can hold multiple silos.

see more

Adjustable speed and stable operation disperser

Application Disperser is designed to mix medium hard materials in liquid media. Dissolver is used for the production of paints, adhesives, cosmetic products, various pastes, dispersions and emulsions, etc. Dispersers can be made in various capacities. Parts and components in contact with the product are made of stainless steel. At the request of the customer, the equipment can still be assembled with an explosion-proof drive The disperser is e... see more

Impulse bags dust collector with high purificat...

Features:

1. High purification efficiency and large processing capacity.

2. Stable performance, long service life of the filter bag and easy operation.

3. Strong cleaning ability, high dust removal efficiency and low emission concentration.

4. Low energy consumption, reliable and stable operation.

see more

Fast palletizing speed and stable High Position...

Capacity: 500~1200 bags per hour

Features & Advantages:

- 1. Fast palletizing speed, up to 1200 bags/hour

- 2. The palletizing process is fully automatic

- 3. Arbitrary palletizing can be realized, which is suitable for the characteristics of many bag types and various coding types

- 4. Low power consumption, beautiful stacking shape, saving operating costs

Single shaft plough share mixer

Features:

1. The plough share head has a wear-resistant coating, which has the characteristics of high wear resistance and long service life.

2. Fly cutters be installed on the wall of the mixer tank, which can quickly disperse the material and make the mixing more uniform and fast.

3. According to different material s and different mixing requirements, the mixing method of the plough share mixer can be regulated, such as mixing time, power, speed, etc., to fully ensure the mixing requirements.

4. High production efficiency and high mixing precision.