Tower type dry mortar production line

Product Detail

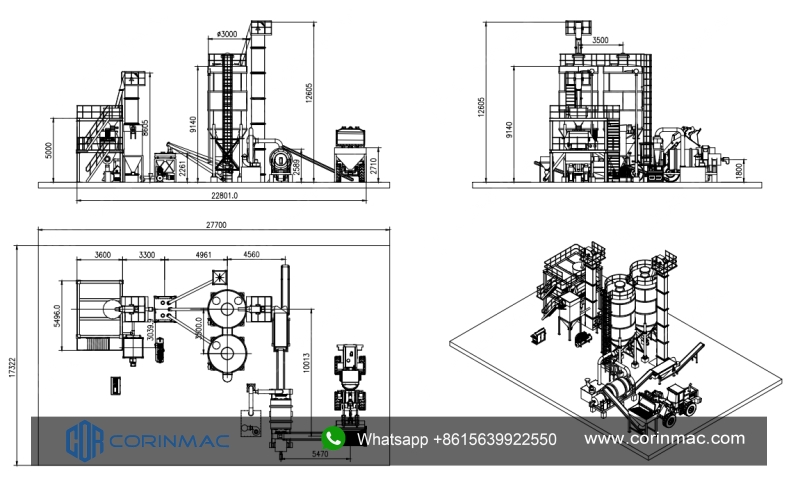

Tower type dry mortar production line

The tower type dry-mix mortar equipment is arranged from top to bottom according to the production process, the production process is smooth, the product variety is large, and the cross-contamination of raw materials is small. It is suitable for the production of ordinary mortar and various special mortars. In addition, the entire production line covers a small area, has a outward appearance, and has relatively low energy consumption. However, compared to other process structures, the initial investment is relatively large.

The production process is as follows

The wet sand is dried by a three-pass dryer, and then conveyed to the classification sieve on the top of the tower through a plate chain bucket elevator. The classification accuracy of the sieve is as high as 85%, which facilitates fine production and stable efficient. The number of screen layers can be set according to different process requirements. In general, four types of products are obtained after the classification of dry sand, which are stored in four raw material tanks at the top of the tower. The cement, gypsum and other raw material tanks are distributed on the side of the main building, and the materials are conveyed by the screw conveyor.

The materials in each raw material tank are transferred to the measuring bin using variable frequency feeding and intelligent electrical technology. The measuring bin has high measurement accuracy, stable operation, and a cone-shaped bin body with no residue.

After the material is weighed, the pneumatic valve below the measuring bin opens and material enters the mixing main machine by self-flow. The configuration of the main machine is usually a dual-shaft gravity-free mixer and a coulter mixer. Short mixing time, high efficiency, energy saving, wear resistance and loss prevention. After the mixing is completed, the materials enter the buffer warehouse. A variety of models of automatic packaging machines are configured under the buffer warehouse. For high-volume production lines, the integrated design of automatic packaging, palletizing, and packaging production can be achieved, saving labor and reducing labor intensity. In addition, an efficient dust removal system is installed to create a good working environment and meet environmental protection requirements.

The entire production line adopts advanced computer synchronous production management and control system, which supports fault early warning, controls product quality, and saves labor costs.

The core equipment of the tower type dry mortar production line:

Mixers and Weighing Systems:

Dry mortar mixer

The dry mortar mixer is the core equipment of the dry mortar production line, which determines the quality of the mortars. Different mortar mixers can be used according to different types of mortar.

Dry mortar mixer

The dry mortar mixer is the core equipment of the dryh mortar production line, which determines the quality of the mortars. Different mortar mixers can be used according to different types of mortar.

Single shaft plough share mixer

The technology of the plough share mixer is mainly from Germany, and it is a mixer commonly used in large-scale dry powder mortar production lines. The plough share mixer is mainly composed of an outer cylinder, a main shaft, plough shares, and plough share handles. The rotation of the main shaft drives the plowshare-like blades to rotate at a high speed to drive the material to move rapidly in both directions, so as to achieve the purpose of mixing. The stirring speed is fast, and a flying knife is installed on the wall of the cylinder, which can quickly disperse the material, so that the mixing is more uniform and fast, and the mixing quality is high.

Single shaft plough share mixer(big discharge door)

Single shaft plough share mixer(super high speed)

Weighing hopper

Raw Material Weighing Hopper

Weighing system: precise and stable quality controllable

Adopt high-precision sensor, step feeding, special bellows sensor, cast high-precision measurement and ensure production quality.

Description

The weighing hopper consists of hopper, steel frame, and load cell (the lower part of the weighing bin is equipped with a discharge screw). The weighing hopper is widely used in various mortar lines to weigh ingredients such as cement, sand, fly ash, light calcium, and heavy calcium. It has the advantages of fast batching speed, high measurement accuracy, strong versatility, and can handle various bulk materials.

Working principle

The measuring bin is a closed bin, the lower part is equipped with a discharge screw, and the upper part has a feeding port and a breathing system. Under the instruction of the control center, the materials are sequentially added to the weighing bin according to the set formula. After the measurement is completed, wait for the instructions to send the materials to the bucket elevator inlet of the next link. The entire batching process is controlled by PLC in a centralized control cabinet, with high degree of automation, small error and high production efficiency.

Drawing

Our products

Recommended products

Simple dry mortar production line CRM1

Capacity: 1-3TPH; 3-5TPH; 5-10TPH

Features and Advantages:

1. The production line is compact in structure and occupies a small area.

2. Modular structure, which can be upgraded by adding equipment.

3. The installation is convenient, and the installation can be completed and put into production in a short time.

4. Reliable performance and easy to use.

5. The investment is small, which can quickly recover the cost and create profits.

Dry mortar production line intelligent control ...

Features:

1. Multi-language operating system, English, Russian, Spanish, etc. can be customized according to customer requirements.

2. Visual operation interface.

3. Fully automatic intelligent control.

Simple dry mortar production line CRM2

Capacity: 1-3TPH; 3-5TPH; 5-10TPH

Features and Advantages:

1. Compact structure, small footprint.

2. Equipped with a ton bag unloading machine to process raw materials and reduce the work intensity of workers.

3. Use the weighing hopper to automatically batch ingredients to improve production efficiency.

4. The whole line can realize automatic control.

Simple dry mortar production line CRM3

Capacity: 1-3TPH; 3-5TPH; 5-10TPH

Features and Advantages:

1. Double mixers run at the same time, double the output.

2. A variety of raw material storage equipment is optional, such as ton bag unloader, sand hopper, etc., which are convenient and flexible to configure.

3. Automatic weighing and batching of ingredients.

4. The whole line can realize automatic control and reduce labor cost.