Three cylinder rotary dryer with high heat efficiency

Product Detail

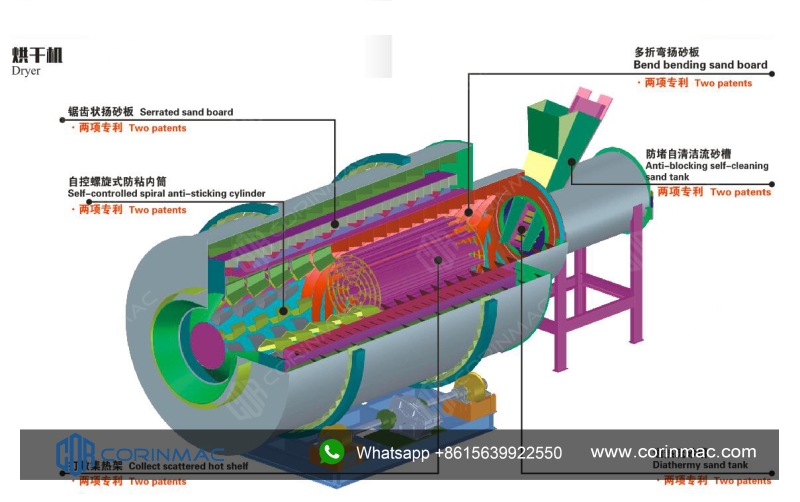

Three cylinder rotary dryer

The three-cylinder rotary dryer is an efficient and energy-saving product improved on the basis of the single-cylinder rotary dryer.

There is a three-layer drum structure in the cylinder, which can make the material reciprocate three times in the cylinder, so that it can obtain sufficient heat exchange, greatly improve the heat utilization rate and reduce power consumption.

Product Details

Working principle

The material enters the dryer inner drum of the dryer from the feeding device to realize downstream drying. The material is continuously lifted up and scattered by the inner lifting plate and travels in a spiral shape to realize heat exchange, while the material moves to the other end of the inner drum then enters the middle drum, and the material is continuously and repeatedly raised in the middle drum, in the way of two steps forward and one step backward, the material in the middle drum fully absorbs the heat emitted by the inner drum and absorbs the heat of the middle drum at the same time, the drying time is prolonged, and the material reaches the best drying state at this time. The material travels to the other end of the middle drum and then falls into the outer drum. The material travels in a rectangular multi-loop way in the outer drum. The material that achieves the drying effect quickly travels and discharges the drum under the action of hot air, and the wet material that has not reached the drying effect cannot travel quickly due to its own weight, and the material is fully dried in this rectangular lifting plates, thereby completing the drying purpose.

Advantages

1. The three cylinder structure of the drying drum increases the contact area between the wet material and the hot air, which reduces the drying time by 48-80% compared with the traditional solution, and the moisture evaporation rate can reach 120-180 kg/m3, and the fuel consumption is reduced by 48-80%. The consumption is 6-8 kg/ton.

2. The drying of the material is not only carried out by the hot air flow, but also carried out by the infrared radiation of the heated metal inside, which improves the heat utilization rate of the whole dryer.

3. The overall size of the dryer is reduced by more than 30% compared to ordinary single-cylinder dryers, thereby reducing external heat loss.

4. The thermal efficiency of the self-insulating dryer is as high as 80% (compared to only 35% for the ordinary rotary dryer), and the thermal efficiency is 45% higher.

5. Due to the compact installation, the floor space is reduced by 50% and the infrastructure cost is reduced by 60%

6. The temperature of the finished product after drying is about 60-70 degrees, so that it does not need an additional cooler for cooling.

7. The exhaust temperature is low, and the life of the dust filter bag is extended by 2 times.

8. The desired final humidity can be easily adjusted according to user requirements.

1 to 1 customized service

We can do different program designs and configurations according to your requirements. We will provide each customer with customized production solutions to meet the requirements of different construction sites, workshops and production equipment layout.

Scope of application

Successful Project

We have many thematic sites in more than 40 countries around the world. Part of our installation sites are as follows:

Product parameters

|

Model |

Outer cylinder dia.(м) |

Outer cylinder length (м) |

Rotating speed (r/min) |

Volume (m³) |

Drying capacity (t/h) |

Power (kw) |

|

HG1520 |

1.5 |

2 |

3-10 |

3.5 |

3-5 |

5.5 |

|

HG2240 |

2 |

4 |

3-10 |

9 |

8-15 |

7.5 |

|

HG2550 |

2.2 |

5 |

3-10 |

15.7 |

15-20 |

2*5.5 |

|

HG2958 |

2.6 |

5.8 |

3-10 |

33 |

30-35 |

4*5.5 |

|

HG3270 |

2.9 |

7 |

3-10 |

41 |

50-60 |

4*11 |

|

HG3890 |

3.4 |

9 |

3-10 |

68 |

80-90 |

4*11 |

Note:

1. These parameters are calculated based on the initial sand moisture content: 10-15%, and the humidity after drying is less than 1%. .

2. The temperature at the inlet of the dryer is 650-750 degrees.

3. The length and diameter of the dryer can be changed according to customer requirements.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

User Feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Drawing

Our products

Recommended products

Drying production line with low energy consumpt...

Features and Advantages:

1. The entire production line adopts an integrated control and visual operation interface.

2. Adjust the material feeding speed and dryer rotating speed by frequency conversion.

3. Burner intelligent control, intelligent temperature control function.

4. The temperature of the dried material is 60-70 degrees, and it can be used directly without cooling.

Rotary dryer with low energy consumption and hi...

Features and Advantages:

1. According to the different materials to be dried, the suitable rotate cylinder structure could be selected.

2. Smooth and reliable operation.

3. Different heat sources are available: natural gas, diesel, coal, biomass particles, etc.

4. Intelligent temperature control.