Products

Reliable performance spiral ribbon mixer

Product Detail

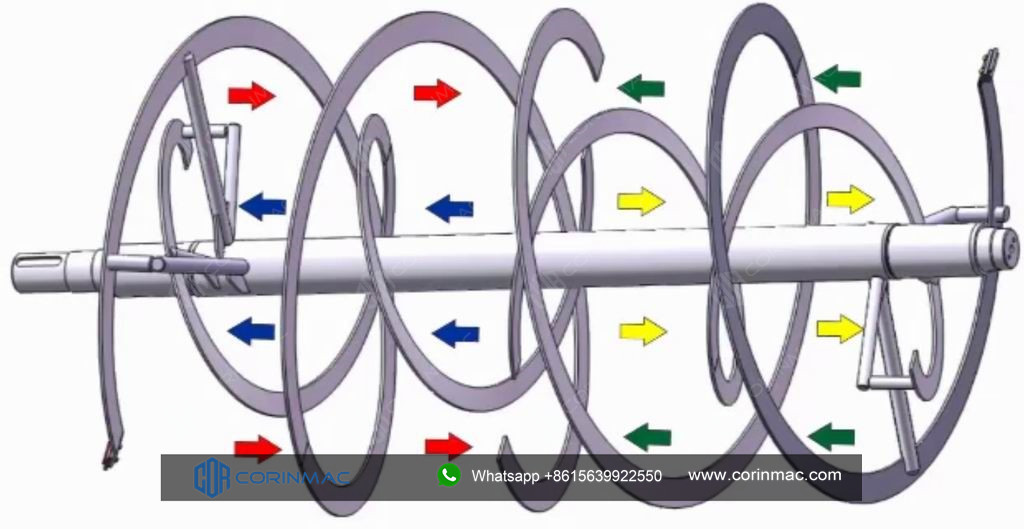

Working principle

The main shaft inside the body of the spiral ribbon mixer is driven by the motor to rotate the ribbon. The thrust face of the spiral belt pushes the material to move in the spiral direction. Due to the mutual friction between the materials, the materials are rolled up and down, and at the same time, a part of the materials is also moved in the spiral direction, and the materials at the center of the spiral belt and the surrounding materials are replaced. Due to the inner and outer reverse spiral belts, the materials form a reciprocating motion in the mixing chamber, the materials are strongly stirred, and the agglomerated materials are broken. Under the action of shear, diffusion and agitation, the materials are evenly mixed.

Structural features

The ribbon mixer is composed of a ribbon, a mixing chamber, a driving device and a frame. The mixing chamber is a semi-cylinder or cylinder with closed ends. The upper part has an openable cover, a feeding port, and the lower part has a discharge port and a discharge valve. The main shaft of the ribbon mixer is equipped with a spiral double ribbon, and the inner and outer layers of the ribbon are rotated in opposite directions. The cross-sectional area of the spiral ribbon, the clearance between the pitch and the inner wall of the container, and the number of turns of the spiral ribbon can be determined according to the material.

Single shaft ribbon mixer

Single shaft ribbon mixer(small discharge door)

Here are three inspection and maintenance at the bottom for easy maintenance

Single shaft ribbon mixer (big discharge door)

Specifications

|

Modle |

Volume (m³) |

Capacity (kg/time) |

Speed (r/min) |

Power (kw) |

Weight (t) |

Overall size (mm) |

|

LH-0.5 |

0.3 |

300 |

62 |

7.5 |

900 |

2670x780x1240 |

|

LH -1 |

0.6 |

600 |

49 |

11 |

1200 |

3140x980x1400 |

|

LH -2 |

1.2 |

1200 |

33 |

15 |

2000 |

3860x1200x1650 |

|

LH -3 |

1.8 |

1800 |

33 |

18.5 |

2500 |

4460x1300x1700 |

|

LH -4 |

2.4 |

2400 |

27 |

22 |

3600 |

4950x1400x2000 |

|

LH -5 |

3 |

3000 |

27 |

30 |

4220 |

5280x1550x2100 |

|

LH -6 |

3.6 |

3600 |

27 |

37 |

4800 |

5530x1560x2200 |

|

LH -8 |

4.8 |

4800 |

22 |

45 |

5300 |

5100x1720x2500 |

|

LH -10 |

6 |

6000 |

22 |

55 |

6500 |

5610x1750x2650 |

Drawing

Our products

Recommended products

Adjustable speed and stable operation disperser

Application Disperser is designed to mix medium hard materials in liquid media. Dissolver is used for the production of paints, adhesives, cosmetic products, various pastes, dispersions and emulsions, etc. Dispersers can be made in various capacities. Parts and components in contact with the product are made of stainless steel. At the request of the customer, the equipment can still be assembled with an explosion-proof drive The disperser is e... see more

Single shaft plough share mixer

Features:

1. The plough share head has a wear-resistant coating, which has the characteristics of high wear resistance and long service life.

2. Fly cutters be installed on the wall of the mixer tank, which can quickly disperse the material and make the mixing more uniform and fast.

3. According to different material s and different mixing requirements, the mixing method of the plough share mixer can be regulated, such as mixing time, power, speed, etc., to fully ensure the mixing requirements.

4. High production efficiency and high mixing precision.

High efficiency double shaft paddle mixer

Features:

1. The mixing blade is cast with alloy steel, which greatly prolongs the service life, and adopts an adjustable and detachable design, which greatly facilitates the use of customers.

2. The direct-connected dual-output reducer is used to increase the torque, and the adjacent blades will not collide.

3. Special sealing technology is used for the discharge port, so the discharge is smooth and never leaks.