Single shaft plough share mixer

Product Detail

Single shaft plough share mixer

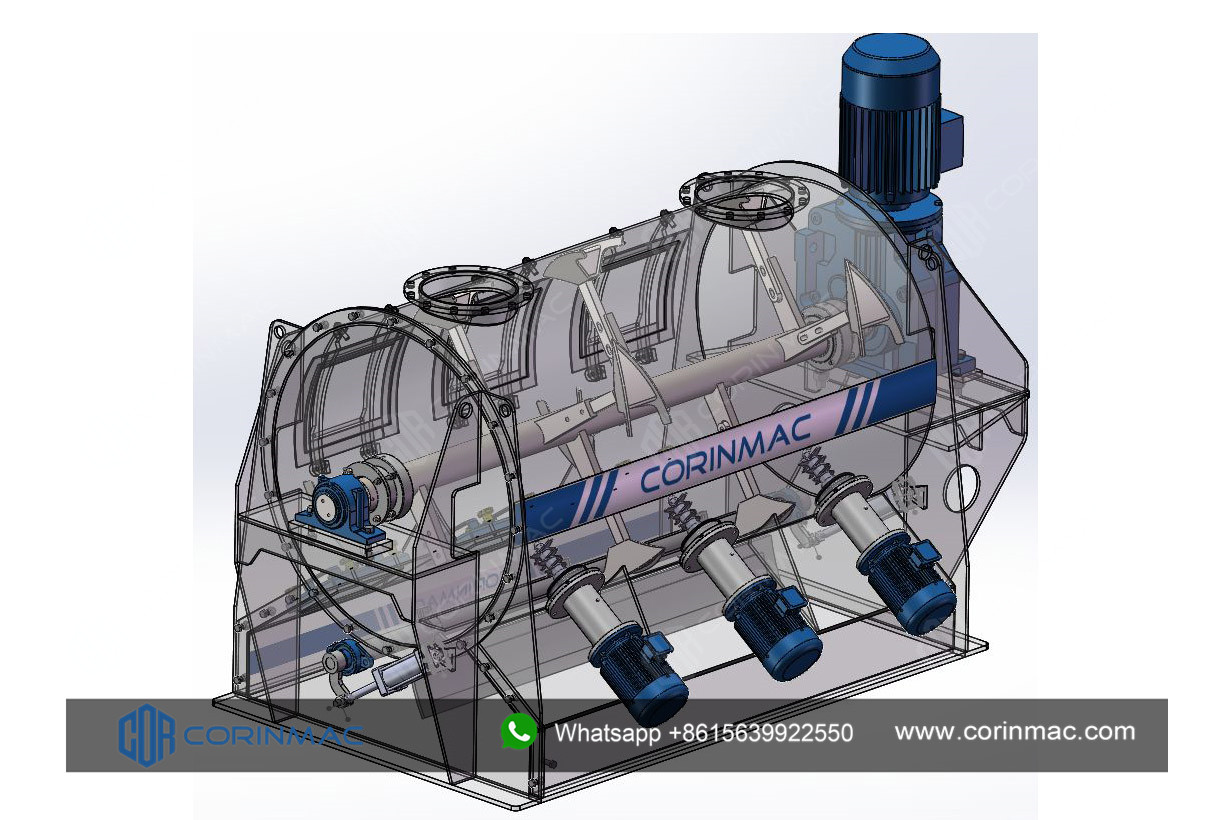

The technology of the plough share mixer is mainly from Germany, and it is a mixer commonly used in large-scale dry powder mortar production lines. The plough share mixer is mainly composed of an outer cylinder, a main shaft, plough shares, and plough share handles. The rotation of the main shaft drives the plowshare-like blades to rotate at a high speed to drive the material to move rapidly in both directions, so as to achieve the purpose of mixing. The stirring speed is fast, and a flying knife is installed on the wall of the cylinder, which can quickly disperse the material, so that the mixing is more uniform and fast, and the mixing quality is high.

The single-shaft mixer (plowshare) is designed for high-quality intensive mixing of dry bulk materials, especially for lumpy materials (such as fibrous or easily tidal agglomeration) in the production of dry mortars, and can also be used in the preparation of compound feed.

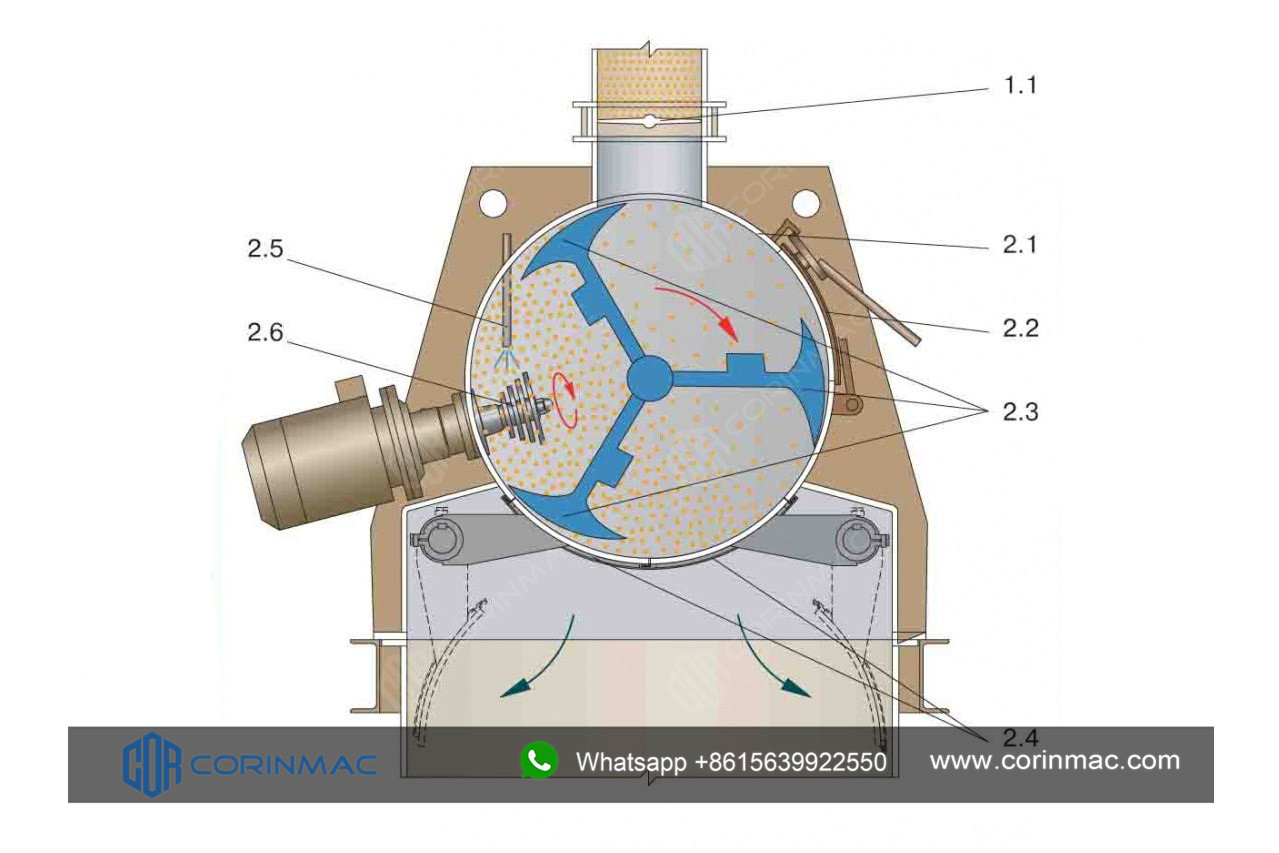

1.1 Feed valve

2.1 Mixer tank

2.2 Observation door

2.3 Plough share

2.4 Discharge port

2.5 Liquid sprinkler

2.6 Flying cutter group

The shape and position of the mixer plough shares ensures the quality and speed of dry mixture mixing, and the plough share feature directional work surfaces and simple geometry, which increases their durability and reduces replacement during maintenance. The working area and discharge port of the mixer are sealed to eliminate dust during discharge.

Working principle

The single-shaft plough share mixer is a single-shaft forced mixing device. Multiple sets of plough share are installed on the main shaft to continuously form a continuous vortex centrifugal force. Under such forces, substances continuously overlap, separate and mix. In such a mixer, a high-speed flying cutter group is also installed. The high-speed flying cutters are located at a 45-degree angle on the side of the mixer body. While separating the bulk materials, the materials are fully mixed.

Single shaft plough share mixer (big discharge door)

High-quality wear-resistant bearing

Equipped with independent air storage tank to ensure air supply pressure

Pneumatic sampler, easy to monitor the mixing effect at any time

Flying cutters could be installed, which can quickly break up the material and make the mixing more uniform and faster.

Single shaft plough share mixer (Supper high speed)

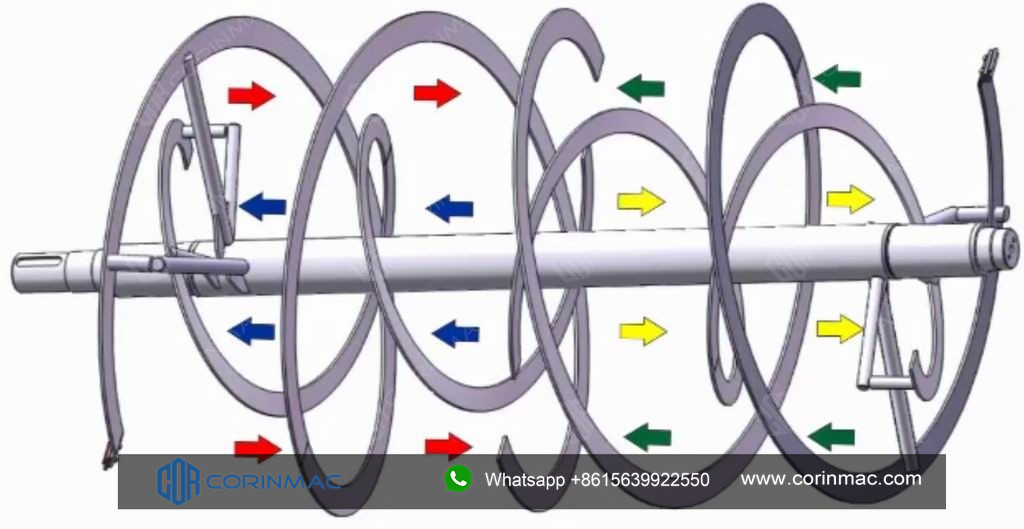

The stirring blades can also be replaced with paddles for different materials

When mix light materials with low abrasiveness, the spiral ribbon could also be replaced. Two or more layers of spiral ribbons could make the outer layer and inner layer of the material move in opposite directions respectively, and the mixing efficiency is higher and more uniform.

Specifications

|

Model |

Volume (m³) |

Cpacity (kg/time) |

Speed (r/min) |

Motor power (kw) |

Weight (t) |

Overall size (mm) |

|

LD-0.5 |

0.3 |

300 |

85 |

5.5+(1.5*2) |

1080 |

1900x1037x1150 |

|

LD-1 |

0.6 |

600 |

63 |

11+(2.2*3) |

1850 |

3080x1330x1290 |

|

LD-2 |

1.2 |

1200 |

63 |

18.5+(3*3) |

2100 |

3260x1404x1637 |

|

LD-3 |

1.8 |

1800 |

63 |

22+(3*3) |

3050 |

3440x1504x1850 |

|

LD-4 |

2.4 |

2400 |

50 |

30+(4*3) |

4300 |

3486x1570x2040 |

|

LD-6 |

3.6 |

3600 |

50 |

37+(4*3) |

6000 |

4142x2105x2360 |

|

LD-8 |

4.8 |

4800 |

42 |

45+(4*4) |

7365 |

4387x2310x2540 |

|

LD-10 |

6 |

6000 |

33 |

55+(4*4) |

8250 |

4908x2310x2683 |

Case III

Kazakhstan-Astana-2 m³ single shaft plough share mixer

Case IV

Kazakhstan- Almaty-2 m³ single shaft plough share mixer

Case V

Russia – Katask- 2 m³ single shaft plough share mixer

Case Vl

Vietnam- 2 m³ single shaft plough share mixer

Drawing

Our products

Recommended products

Adjustable speed and stable operation disperser

Application Disperser is designed to mix medium hard materials in liquid media. Dissolver is used for the production of paints, adhesives, cosmetic products, various pastes, dispersions and emulsions, etc. Dispersers can be made in various capacities. Parts and components in contact with the product are made of stainless steel. At the request of the customer, the equipment can still be assembled with an explosion-proof drive The disperser is e... see more

High efficiency double shaft paddle mixer

Features:

1. The mixing blade is cast with alloy steel, which greatly prolongs the service life, and adopts an adjustable and detachable design, which greatly facilitates the use of customers.

2. The direct-connected dual-output reducer is used to increase the torque, and the adjacent blades will not collide.

3. Special sealing technology is used for the discharge port, so the discharge is smooth and never leaks.

Reliable performance spiral ribbon mixer

The Spiral ribbon mixer is mainly composed of a main shaft, double-layer or multi-layer ribbon. The spiral ribbon is one outside and one inside, in opposite directions, pushes the material back and forth, and finally achieves the purpose of mixing, which is suitable for stirring light materials.

see more