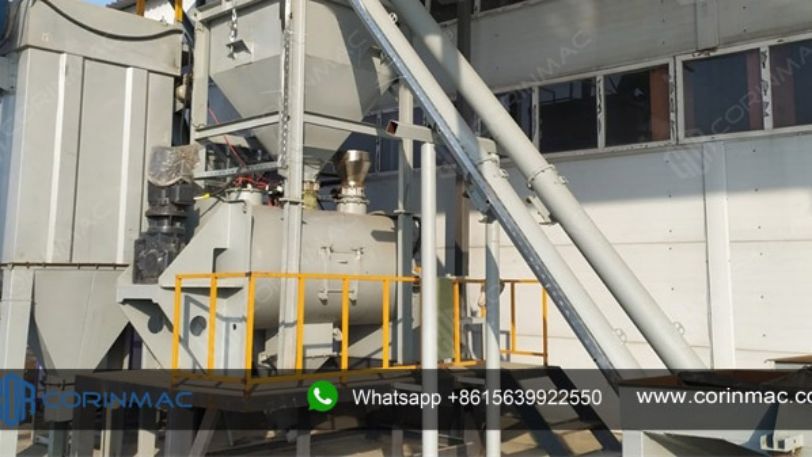

Splicable and stable sheet silo

Product Detail

Silo for cement, sand, lime, etc.

Sheet cement silo is a new type of silo body, also called split cement silo (split cement tank). All parts of this type of silo are completed by machining, which gets rid of the defects of roughness and limited conditions caused by manual welding and gas cutting caused by traditional on-site production. It has beautiful appearance, short production period, convenient installation, and centralized transportation. After use, it can be transferred and reused, and it is not affected by the site conditions of the construction site.

Loading of cement into the silo is carried out via a pneumatic cement pipeline. To prevent material hanging and ensure uninterrupted unloading, an aeration system is installed in the lower (conical) part of the silo.

The supply of cement from the silo is carried out mainly by a screw conveyor.

To control the level of material in the silos, high and low level gauges are installed on the silo body. Also, the silos are equipped with filters with a system of impulse blowing of filter elements with compressed air, which has both remote and local control. The cartridge filter is installed on the upper platform of the silo, and serves to clean the dusty air escaping from the silo under the influence of excess pressure when loading cement.

Installation steps guidance

Drawing

Our products

Recommended products

Screw conveyor with unique sealing technology

Features:

1. The external bearing is adopted to prevent dust from entering and prolong the service life.

2. High quality reducer, stable and reliable.

see more

Fast palletizing speed and stable High Position...

Capacity: 500~1200 bags per hour

Features & Advantages:

- 1. Fast palletizing speed, up to 1200 bags/hour

- 2. The palletizing process is fully automatic

- 3. Arbitrary palletizing can be realized, which is suitable for the characteristics of many bag types and various coding types

- 4. Low power consumption, beautiful stacking shape, saving operating costs

Reliable performance spiral ribbon mixer

The Spiral ribbon mixer is mainly composed of a main shaft, double-layer or multi-layer ribbon. The spiral ribbon is one outside and one inside, in opposite directions, pushes the material back and forth, and finally achieves the purpose of mixing, which is suitable for stirring light materials.

see more

Drying production line with low energy consumpt...

Features and Advantages:

1. The entire production line adopts an integrated control and visual operation interface.

2. Adjust the material feeding speed and dryer rotating speed by frequency conversion.

3. Burner intelligent control, intelligent temperature control function.

4. The temperature of the dried material is 60-70 degrees, and it can be used directly without cooling.

Vibrating screen with high screening efficiency...

Features:

1. Wide range of use, the sieved material has uniform particle size and high sieving accuracy.

2. The screen layers quantity can be determined according to different needs.

3. Easy maintenance and low maintenance probability.

4. Using the vibration excitors with adjustable angle, the screen is clean; the multi-layer design can be used, the output is large; the negative pressure can be evacuated, and the environment is good.

see more

High precision open bag packaging machine

Capacity: 4-6 bags per minute; 10-50 kg per bag

Features and Advantages:

- 1. Fast packaging and wide application

- 2. High degree of automation

- 3. High packaging precision

- 4. Excellent environmental indicators and non-standard customization