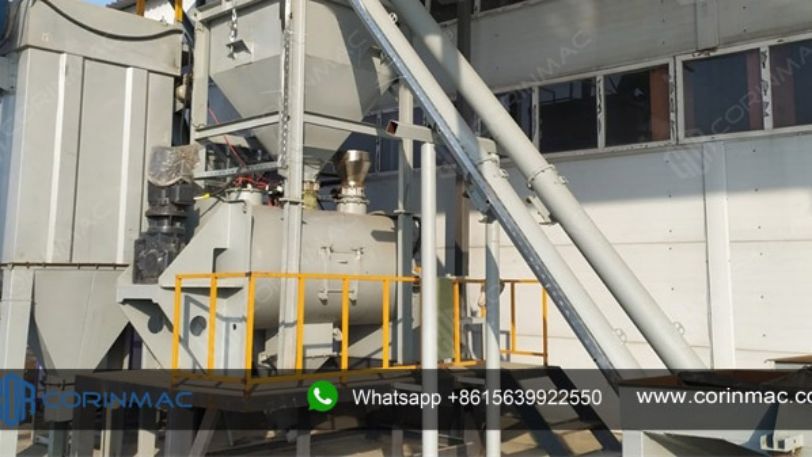

Screw conveyor with unique sealing technology

Product Detail

Screw conveyor

The screw conveyor (screws) are designed for horizontal and inclined transportation of small lumpy, granular, powdery, explosion-proof, non-aggressive materials of various origins. Screw conveyors are usually used as feeders, batching conveyors in the production of dry mortar.

The external bearing is adopted to prevent dust from entering and prolong the service life.

High-quality reducer, stable and reliable.

The simplicity of the design, high performance, reliability and unpretentiousness of screw conveyors determine their widespread use in various areas of production activity associated with the movement of large volumes of bulk material.

Screw conveyor

|

Model |

LSY100 |

LSY120 |

LSY140 |

LSY160 |

LSY200 |

LSY250 |

LSY300 |

|

|

Screw dia. (mm) |

Φ88 |

Φ108 |

Φ140 |

Φ163 |

Φ187 |

Φ240 |

Φ290 |

|

|

Shell outside dia.(mm) |

Φ114 |

Φ133 |

Φ168 |

Φ194 |

Φ219 |

Φ273 |

Φ325 |

|

|

Working angle |

0°-60° |

0°-60° |

0°-60° |

0°-60° |

0°-60° |

0°-60° |

0°-60° |

|

|

Coveying length(m) |

8 |

8 |

10 |

12 |

14 |

15 |

18 |

|

|

Cement density ρ=1.2t/m3,Angle 35°-45° |

||||||||

|

Capacity(t/h) |

6 |

12 |

20 |

35 |

55 |

80 |

110 |

|

|

According to the density of fly ash ρ=0.7t/m3,Angle 35°-45° |

||||||||

|

Capacity (t/h) |

3 |

5 |

8 |

20 |

32 |

42 |

65 |

|

|

Motor |

Power (kW) L≤7 |

0.75-1.1 |

1.1-2.2 |

2.2-3 |

3-5.5 |

3-7.5 |

4-11 |

5.5-15 |

|

Power (kW) L>7 |

1.1-2.2 |

2.2-3 |

4-5.5 |

5.5-11 |

7.5-11 |

11-18.5 |

15-22 |

|

Installation steps guidance

Drawing

Our products

Recommended products

Durable and smooth-running belt feeder

Features:

The belt feeder is equipped with a variable frequency speed regulating motor, and the feeding speed can be adjusted arbitrarily to achieve the best drying effect ore other requirement.

It adopts skirt conveyor belt to prevent material leakage.

see more

Stable operation and large conveying capacity b...

Bucket elevator is a widely used vertical conveying equipment. It is used for vertical conveying of powder, granular and bulk materials, as well as highly abrasive materials, such as cement, sand, soil coal, sand, etc. The material temperature is generally below 250 °C, and the lifting height can reach 50 meters.

Conveying capacity: 10-450m³/h

Scope of application: and widely used in building materials, electric power, metallurgy, machinery, chemical industry, mining and other industries.

see more