High precision open bag packaging machine

Product Detail

Introduction

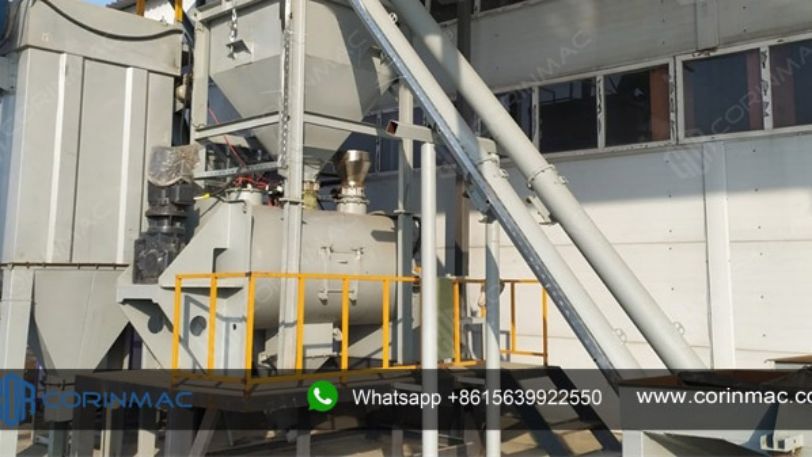

The open bag filling machine is specially designed for open bag packaging of powder and granular materials of 10-50 kg. It adopts the quantitative gravimeter method and controls the feeding speed through the output signal of the load cell to achieve the purpose of automatic packaging. There are various feeding methods for open bag packaging machines, including screw feeding, belt feeding, large and small valve feeding, vibration feeding, etc. The equipment has a wide range of applications, and can pack various powders, ultra-fine powders or fine-grained materials, and is widely used in all walks of life.

In the actual packaging process, the packaging machine is generally used in conjunction with a sealing machine (seam sealing machine or heat sealing machine) and a belt conveyor.

Material Requirements: Materials with certain fluidity

Package Range: 10-50 kg

Application Field: Suitable for the packaging of dry powder mortar, lithium battery materials, calcium carbonate, cement and other industrial products.

Applicable Materials: Materials with certain fluidity, such as dry-mixed mortar, dry concrete, cement, sand, lime, slag, etc.

Advantages

Fast packaging and wide application

Open bag packaging machines with different feeding methods can be customized according to process requirements, which can meet the packaging speed requirements of system production and the packaging of various materials.

High degree of automation

One person can complete open bag filling, automatic bag clamping, weighing, and bag loosening.

High packaging precision

Using a well-known load cell, the accuracy of the weighing platform can reach more than 2/10000, ensuring the packaging accuracy.

Excellent environmental indicators and non-standard customization

It can be equipped with a dust removal port, connected with a dust collector, and has a good on-site environment; explosion-proof packaging machines, all-stainless steel packaging machines, etc. can be customized according to needs.

Working principle

The open bag packaging machine is composed of a control system, a feeder, a weighing sensor, a bag-clamping weighing device, a sewing mechanism, a conveyor belt, a frame, and a pneumatic control system. The feeding system adopts two-speed feeding, fast feeding ensures output, and slow feeding frequency conversion control ensures accuracy; the bag clamping weighing system is composed of weighing brackets, sensors, and bag clamping arms; the frame supports the entire system to ensure stability and firmness; The control system controls the feeding valve and bag clamping. The product packaging form adopts the bag clamping in place, and at the same time there is enough material in the storage hopper, the valve is automatically opened, the material is discharged into the bag, and the weighing is carried out at the same time. When the first set weight is reached, the slow feeding continues until the second set weight value is reached, stop filling, display the final weighing, and lose the bag automatically.

Installation steps guidance