-

Dry mortar mixing production plant with sand drying to Shimkent

Project Location: Shimkent, Kzazkhstan.

Build Time: Jan 2020.

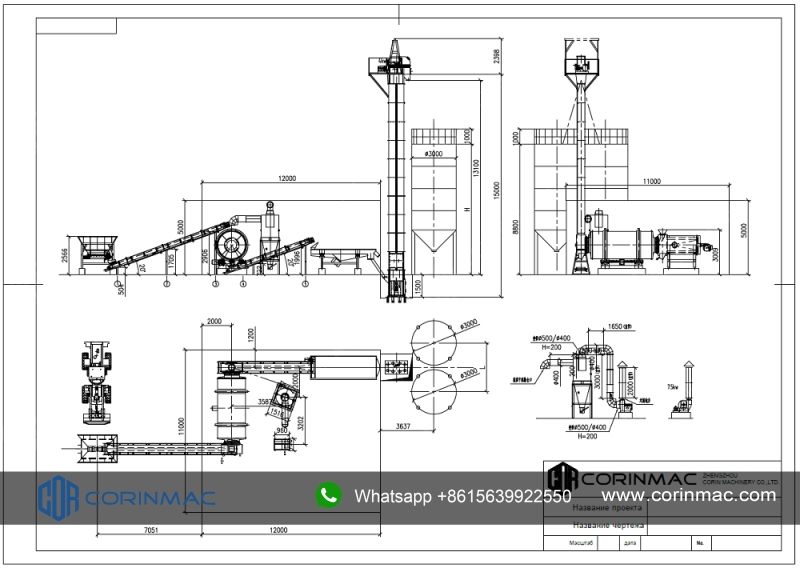

Project Name: 1set 10tph sand drying plant + 1set JW2 10tph dry mortar mixing production plant.On day Jan 06, all equipment were loaded into containers in factory. The main equipment for drying plant is the CRH6210 three cylinder rotary dryer, sand drying plant includs wet sand hopper, conveyors, rotary dryer, and vibrating screen. The screened dry sand will be stored into 100T silos and used for the dry mortar production. The mixer is JW2 double shaft paddle mixer, which we called weightless mixer also. This is a complete, typical dry mortar production line, different mortars can be made on request.

Customer evaluation

"Thanks very much for CORINMAC's assistance throughout the process, which enabled our production line to be put into production quickly. I am also very happy to have established our friendship with CORINMAC through this cooperation. Hope we all get better and better, just like the name of CORINMAC company, win-win cooperation!"

---ZAFAL

-

Gypsum mortar & Cement mortar production line

Project Location: Tashkent-Uzbekistan.

Build Time: July 2019.

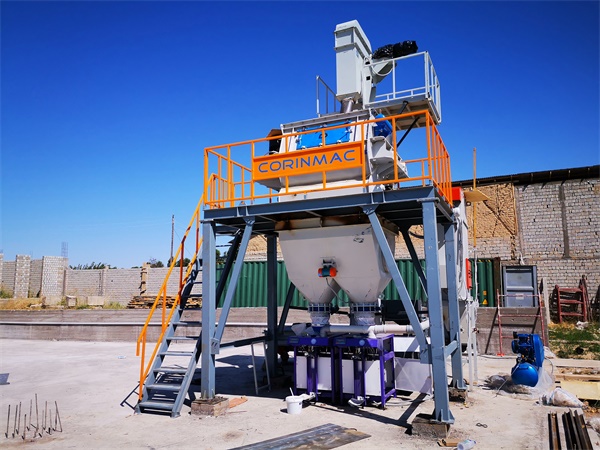

Project Name: 2 sets of 10TPH dry mortar production line ( 1set of gypsum mortar production line + 1 set of cement mortar production line).

In recent years, Uzbekistan has a great demand for building materials, especially Tashkent, the capital of Uzbekistan, is building a number of urban infrastructure and construction projects, including two subway lines and large commercial centers and living centers. According to the statistics of Uzbekistan's statistics department, the import value of building materials from January to March 2019 reached 219 million US dollars, which fully shows that the demand for building materials in Uzbekistan is on the rise.

We know that building materials are divided into structural building materials and decorative building materials, and decorative building materials include marble, tiles, coatings, paints, bathroom materials, etc. Therefore, the demand for dry-mixed mortar in the field of decorative construction is also rising rapidly. Customer who cooperated with us this time saw this opportunity. After detailed investigation and comparison, they finally chose to cooperate with us CORINMAC to build 2 sets of 10TPH dry mortar production lines in Tashkent, one of which is gypsum mortar production line and the other is cement mortar production line.

Our company's business representatives have a detailed understanding of the customer's needs and actual situation, and have carried out a detailed program design.

This production line has a compact structure. According to the height of the plant, we have set up 3 square sand hoppers for storing 3 different grain sizes of sand (0-0.15mm, 0.15-0.63mm, 0.63-1.2mm), and a vertical structure is adopted. After mixing process, the finished mortar is directly dropped into the finished product hopper by gravity for packing. Production efficiency is greatly improved.Our company sent engineers to the working site to provide all-round and whole-process assistance and guidance from the preliminary site layout, to the assembly, commissioning, and trial run of the production line, saving the customer's time, enabling the project to be put into production quickly and creating value.

Customer evaluation

"Thanks very much for CORINMAC's assistance throughout the process, which enabled our production line to be put into production quickly. I am also very happy to have established our friendship with CORINMAC through this cooperation. Hope we all get better and better, just like the name of CORINMAC company, win-win cooperation!"

---ZAFAL