-

1m³ single shaft paddle mixer was delivered to Shymkent, Kazakhstan

Time: June 12, 2024.

Location: Shymkent, Kazakhstan.

Event: On June 12, 2024, CORINMAC 1m³ single shaft paddle mixer, bucket elevator, screw conveyor, packing machine, and filter press, etc were delivered to Shymkent, Kazakhstan.

The mixer is the core equipment of the dry mortar production line. The material of the mixer equipment could be customized according to user needs, such as SS201, SS304 stainless steel, wear-resistant alloy steel, etc.

We will provide each customer with customized production solutions to meet the requirements of different construction sites, workshops and production equipment layout.

-

3-5TPH dry mortar production line equipment was delivered to Yekaterinburg, Russia

Time: June 7, 2024.

Location: Yekaterinburg, Russia.

Event: On June 7, 2024, CORINMAC 3-5TPH dry mortar production line equipment was delivered to Yekaterinburg, Russia.

The whole set of dry mortar production line equipment including JYW-2 paddle mixer machine, ton bag un-loader, electric hoist, screw conveyor, finished product hopper, TD250x7m bucket elevator, electric control cabinet, and packaging machine, etc.

CORINMAC is professional dry mortar production line manufacturer. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs.

-

Sand drying production line was shipped to Donetsk, Russia.

Time: May 20, 2024.

Location: Donetsk, Russia.

Event: On May 20, 2024, CORINMAC sand drying production line equipment was shipped to Donetsk, Russia.

The drying production line is a complete set of equipment for heat drying and screening sand or other bulk materials. It consists of the following parts: wet sand hopper, belt feeder, belt conveyor, burning chamber, rotary dryer (three-cylinder dryer, single-cylinder dryer), cyclone, pulse dust collector, draught fan, vibrating screen, and electronic control system.

The three-cylinder rotary dryer is well received by users because of its high drying efficiency and low energy consumption. The dryers can be selected from a wide range of capacity, from 3TPH to 60TPH.

Because sand is the most commonly used raw material for dry mortars, the drying production line is often used in conjunction with the dry mortar production line.

-

3-5TPH simple dry mortar production line was shipped to Madagascar

Time: May 14, 2024.

Location: Madagascar.

Event: On May 14, 2024, one set of CORINMAC 3-5TPH simple dry mortar production line was shipped to Madagascar.

The simple dry mortar production line is suitable for the production of powder products such as tile adhesive, wall putty, and skim coat, etc. From raw materials feeding to finished product packaging, the whole set of equipment is simple and practical, occupies small area, requires low investment and low maintenance cost.

It is ideal for small process plants and new entrants to this industry. According to the needs of different users, after years of practice and accumulation, CORINMAC has CRM series production solutions with multiple configurations for you to choose from.

-

Bucket elevator was sent to Armenia

Time: April 27, 2024.

Location: Armenia.

Event: On April 27, 2024, one set of CORINMAC bucket elevator was sent to Armenia.

Bucket elevator is a part of the dry mortar production line. It is widely used for vertical conveying of powder, granular and bulk materials, as well as highly abrasive materials, such as cement, sand, soil coal, etc. The material temperature is generally below 250 °C, and the lifting height can reach 50 meters. Conveying capacity: 10-450m³/h. It is widely used in building materials, electric power, metallurgy, machinery, chemical industry, mining and other industries.

If you have any needs for dry mortar machine, please feel free to contact us!

-

Simple dry mortar production line was shipped to Uzbekistan

Time: January 5, 2024.

Location: Uzbekistan.

Event: On January 5, 2024, CORINMAC simple dry mortar production line was shipped to Uzbekistan. Hope our high quality dry mortar machines create more value for our customer.

CORINMAC simple dry mortar plant is suitable for the production of dry mortar. The whole set of equipment consists of spiral ribbon mixer, finished product hopper, screw conveyor, valve bag packing machine and control cabinet, etc. From raw materials feeding to finished product packaging, the whole set of equipment is simple and practical, occupies small area, requires low investment and low maintenance cost.

If you have any needs for dry mortar machine, please feel free to contact us!

-

30-35 tons per hour sand drying production line was delivered to Novosibirsk, Russia.

Time: April 19, 2024.

Location: Novosibirsk, Russia.

Event: On April 19, 2024, CORINMAC one set of drying equipment was delivered to Novosibirsk, Russia.

This is the second time the customer has ordered our sand drying production line.

The capacity of the first set was 15-20 tons per hour, which can not meet the customer's production needs. This time we provide customers with a dryer with cylinder diameter of 2.9 meters and cylinder length of 5.8 meters. The capacity can reach 30-35 tons per hour.

Because of the cold winter in Novosibirsk, we have added insulation layers to the dryer cylinder and pulse dust collector according to the local climate conditions to ensure that the dryer does not lose heat, and the pulse dust collector does not condense water and block the filter bags.

-

Dry mortar production line was delivered to Almaty

Time: April 24, 2024.

Location: Almaty, Kazakhstan.

Event: On April 24, 2024, CORINMAC delivered a mortar production line to PREMIX PRO, a famous dry mortar manufacturer in Kazakhstan. This is the sixth production line we have cooperated with and delivered to PREMIX PRO.

PREMIX PRO has production lines in Almaty, Astana, Aktobe and other cities in Kazakhstan. It is a well-known dry mortar manufacturer in Kazakhstan.

In June 2023, we also paid a return visit to PREMIX PRO Company, and went to the working site to check the use of production equipment, and communicated with customers on equipment improvement plans to ensure that we continue to provide customers with higher quality and more reliable products.

-

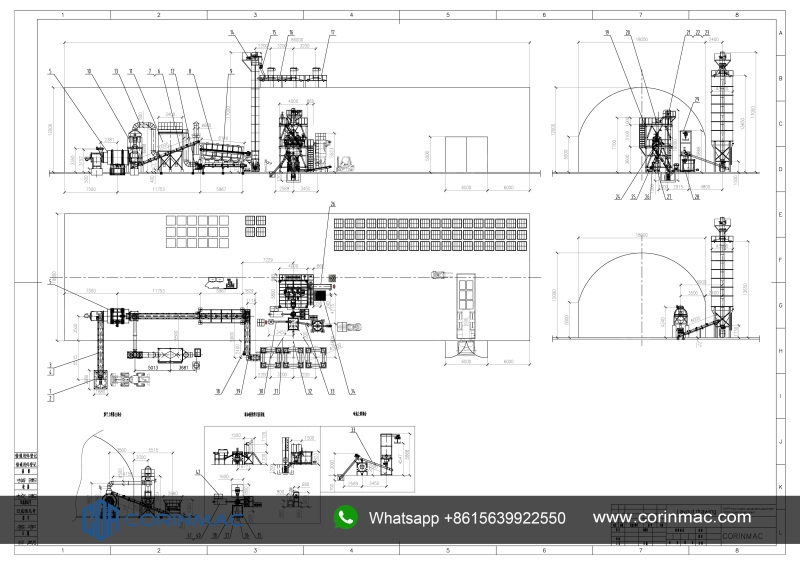

Special mortar production line for Kazakhstan’s construction industry

Time: July 5, 2022.

Location: Shymkent, Kazakhstan.

Event: We provided the user with a set of dry powder mortar production line with a production capacity of 10TPH, including sand drying and screening equipment.

The dry mixed mortar market in Kazakhstan is growing, especially in the residential and commercial construction sectors. As Shymkent is the capital of Shymkent Region, this city may play an important role in the region's construction and building materials market.

Furthermore, the Kazakhstani government has taken a series of measures to develop the construction industry, such as implementing infrastructure projects, promoting housing construction, attracting foreign investment, and others. These policies may stimulate the demand and development of the dry mixed mortar market.

It has always been our company's goal to design reasonable solutions for users, help customers establish efficient and high-quality mortar production lines, and enable customers to achieve production requirements as soon as possible.

In July 2022, through multiple communications with the customer, we finally finalized the plan for a 10TPH special mortar production line. According to the user's workhouse, the plan layout is as follows:

This project is a standard dry mortar production line, including a raw sand drying system. According to user requirements, the trommel screen is used for sieving the sand after drying.

The raw material batching part is composed of two parts: main ingredient batching and additive batching, and the weighing accuracy can reach 0.5%. The mixer adopts our newly developed single-shaft plough share mixer, which has a fast speed and only needs 2-3 minutes for each batch of mixing. The packing machine adopts the air flotation packaging machine, which is more environmentally friendly and efficient.

Now the whole production line has entered the stage of commissioning and operation, and our friend has great confidence in the equipment, which is of course, because this is a set of mature production line which has been verified by many users, and will immediately bring rich benefits to our friend.

-

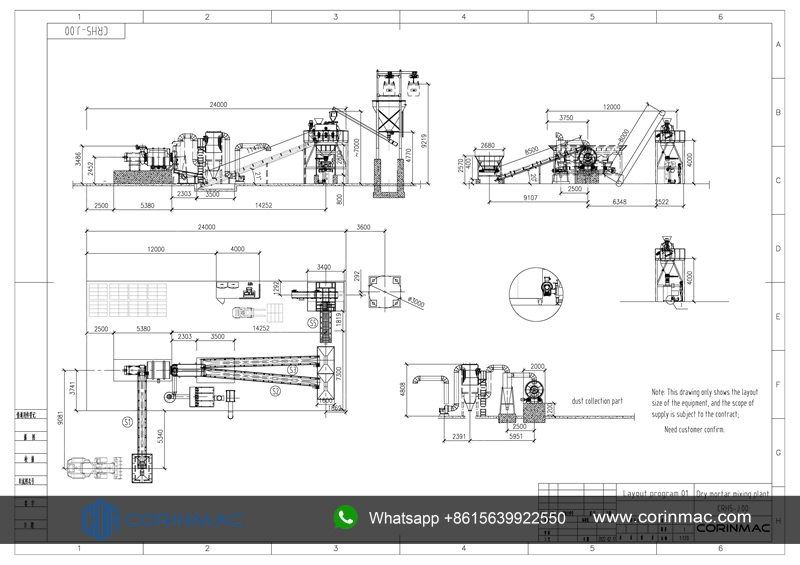

Pioneering customer embraces 3d concrete mortar printing technology

Time: February 18, 2022.

Location: Curacao.

Equipment status: 5TPH 3D printing concrete mortar production line.

At present, concrete mortar 3D printing technology has made great progress and has been widely used in the construction and infrastructure industries. The technology allows for the creation of complex shapes and structures that are difficult or impossible to achieve with traditional concrete casting methods. 3D printing also offers benefits such as faster production, reduced waste, and increased efficiency.

The market for 3D printing dry concrete mortar in the world is driven by a growing demand for sustainable and innovative building solutions, as well as advancements in 3D printing technology. The technology has been used in a range of construction applications, from architectural models to full-scale buildings, and has the potential to revolutionize the industry.

The prospect of this technology is also very broad, and it is expected to become the mainstream of the construction industry in the future. So far, we have had many users set foot in this field and started to apply the concrete mortar 3D printing technology into practice.

Our this customer is a pioneer in the 3D concrete mortar printing industry. After several months of communication between us, the final plan confirmed is as follows.

After drying and screening, the aggregate enters the batching hopper for weighing according to the formula, and then enters the mixer through the large-inclination belt conveyor. The ton-bag cement is unloaded through the ton-bag unloader, and enters the cement weighing hopper above the mixer through the screw conveyor, then enters the mixer. For additive, it enters the mixer through the special additive feeding hopper equipment on mixer top. We used a 2m³ single shaft plough share mixer in this production line, which is suitable for mixing large-grained aggregates, and finally the finished mortar be packed in two ways, open top bags and valve bags.

-

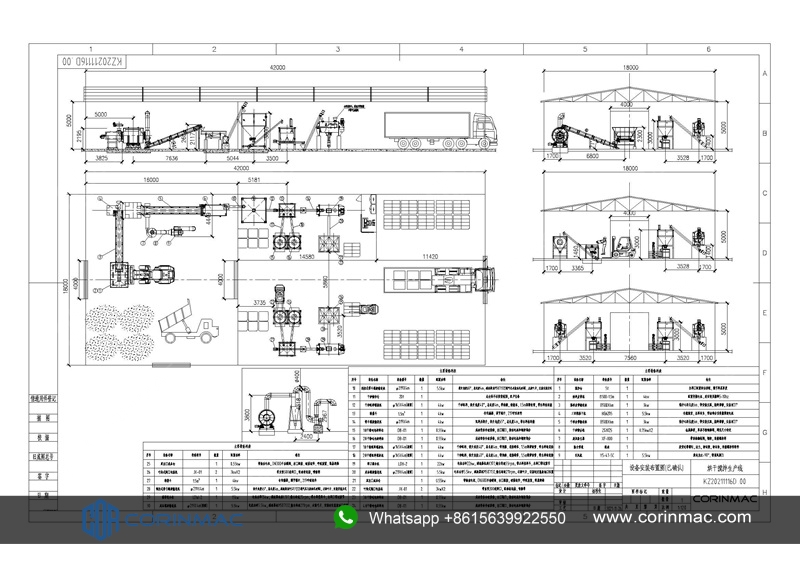

Customized dry mortar production line in low workshops

Time: November 20, 2021.

Location: Aktau, Kazakhstan.

Equipment situation: 1 set of 5TPH sand drying line + 2 sets of flat 5TPH mortar production line.

According to a report published in 2020, the dry mixed mortar market in Kazakhstan is expected to grow at a CAGR of around 9% during the period 2020-2025. The growth is driven by increasing construction activities in the country, which are supported by government initiatives infrastructure development program.

In terms of products, cement-based mortar as the dominant segment in the dry mixed mortar market, accounting for the majority of the market share. However, polymer-modified mortar and other types of mortar are expected to gain popularity in the coming years due to their superior properties such as improved adhesion and flexibility.

Different customers have workshops with different areas and heights, so even under the same production requirements, we will arrange equipment according to different user site conditions.

This user's factory building covers an area of 750㎡, and the height is 5 meters. Although the height of the workhouse is limited, it is very suitable for the layout of our flat mortar production line. The following is the final production line layout diagram we confirmed.

The following is the production line completed and put into production

The raw material sand is stored in the dry sand bin after being dried and screened. Other raw materials are unloaded through the ton bag unloader. Each raw material is accurately bathed through the weighing and batching system, and then enters the high-efficiency mixer through the screw conveyor for mixing, and finally passes through the screw conveyor enters the finished product hoppe for final bagging and packaging. The whole production line is controlled by PLC control cabinet to realize automatic operation.

The whole production line is simple and efficient, running smoothly.

-

Refractory material production line to Malaysia

Project Location: Malaysia.

Build Time: November 2021.

Project Name: On day Sep 04, we delivery this plant to Malaysia. This is a refractory material production plant, compared with normal dry mortar, refractory material needs more kinds of raw mateiral to mix. The whole batching system we designed and made has been highly aprrasied by our customer. For the mixing part, it adopts planetary mixer, it's standard mixer for refractory production.If you have relative requirments, contact with us freely please!