Impulse bags dust collector with high purification efficiency

Product Detail

Impulse dust collector

Pulse dust collector adopts a cleaning method using pulse spraying. The interior contains multiple cylindrical high-temperature resistance filter bags, and the box is made by strict welding process. The inspection doors are sealed with plastic rubber, so it can ensure that the whole machine is tight and does not leak air. It has advantages of high efficiency, large processing air volume, long filter bag life, small maintenance workload, safe and reliable operation, etc. It is widely used in dust removal and purification of non-fibrous dust in various industrial and mining enterprises like metallurgical, construction, machinery, chemical, and mining etc. This product is mainly composed of a box body, air filter bags, ash hopper, gas pipe, pulse valves, a fan and a controller.

Working principle

Dust-containing gas enters the interior of the dust collector from the air inlet. Due to the rapid expansion of the gas volume, some of the coarse dust particles fall into the ash bucket due to inertia or natural settlement, most of the remaining dust particles enter the bag chamber with the airflow. After filtering through the filter bag, the dust particles are retained on the outside of the filter bag. When the dust on the surface of the filter bag continues to increase, causing the equipment resistance to rise to the set value, the time relay (or differential pressure controller) outputs a signal and the program controller starts to work. The pulse valves are opened one by one, so that the compressed air is sprayed through the nozzle, so that the filter bag suddenly expands. Under the action of reverse airflow, the dust attached to the surface of the filter bag quickly leaves the filter bag and falls into the ash hopper (Or ash bin), the dust is discharged by the ash discharge valve, the purified gas enters the upper box from the inside of the filter bag, and then is discharged into the atmosphere through the valve plate hole and the air outlet, so as to achieve the purpose of dust removal.

It is another dust removal equipment in the drying line. Its internal multi-group filter bag structure and pulse jet design can effectively filter and collect dust in the dust-laden air, so that the dust content of the exhaust air is less than 50mg/m³, ensuring that it meets the environmental protection requirements. According to the needs, we have dozens of models such as DMC32, DMC64, DMC112 for selection.

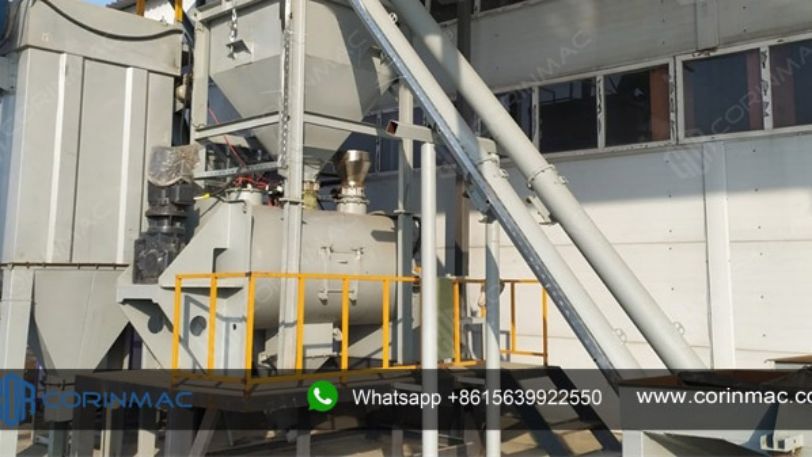

Schematic diagram of the matching use of pulse dust collector and cyclone dust collector

Installation steps guidance

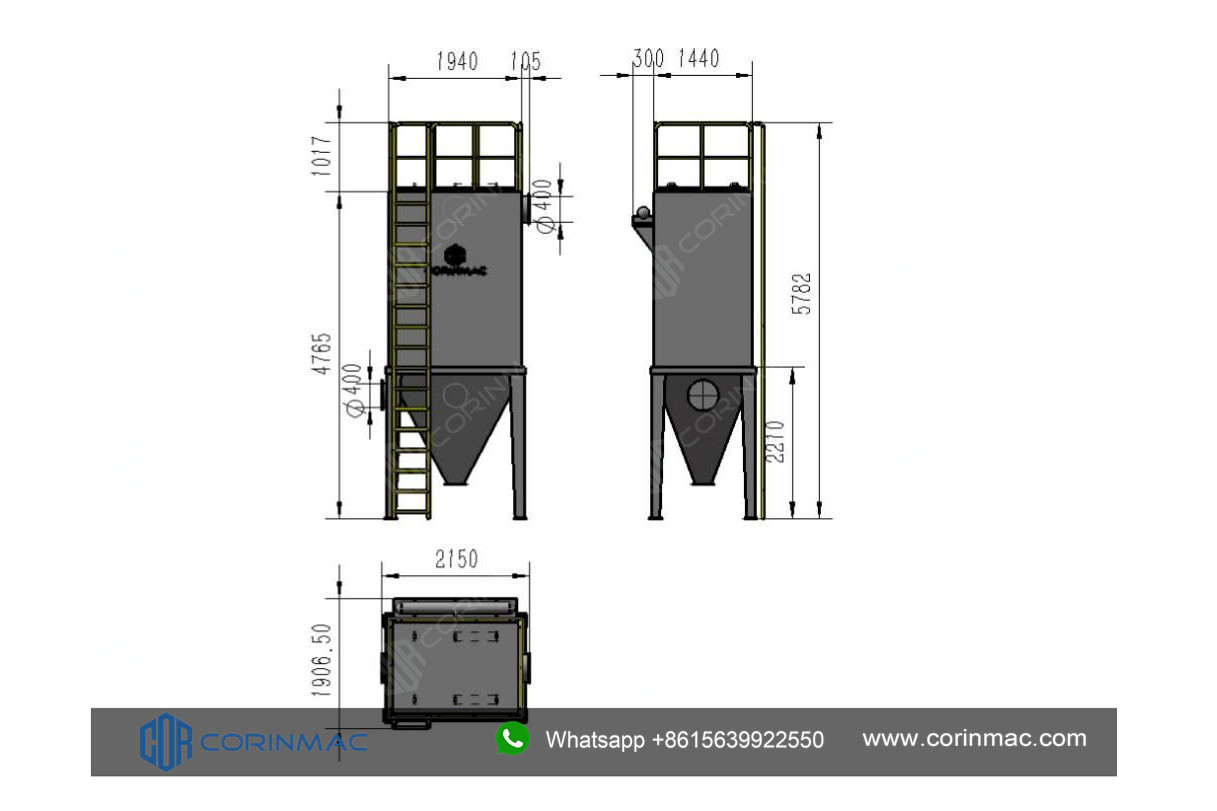

Drawing

Our products

Recommended products

High purification efficiency cyclone dust colle...

Features:

1. The cyclone dust collector has a simple structure and is easy to manufacture.

2. Installation and maintenance management, equipment investment and operating costs are low.

see more