Fast palletizing speed and stable High Position Palletizer

Product Detail

Introduction

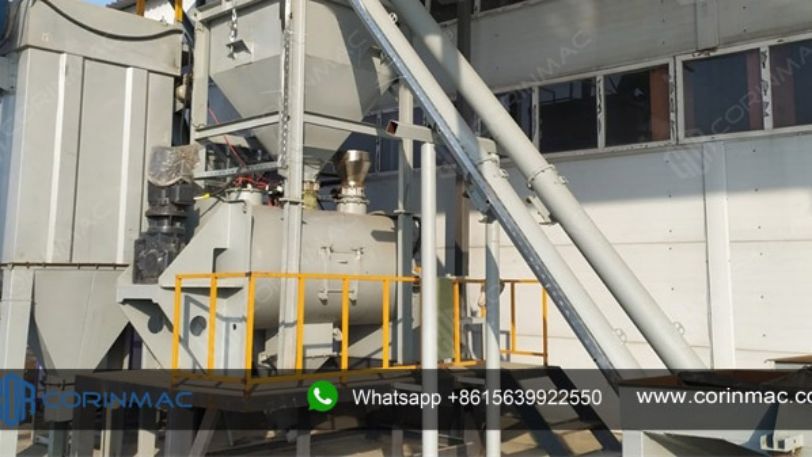

High-position palletizer is a palletizing equipment suitable for large enterprises. It is mainly composed of flattening conveyor, slow-stop conveyor, coner conveyor, pallet depot, pallet conveyor, marshalling machine, bag pushing device, palletizing device, and finished pallet conveyor. Its structure design is optimized, the action is stable and reliable, the palletizing speed is fast, and the stability is relatively high. Easy to maintain, the palletizing process is completely automatic, no manual intervention is required during normal operation, and it has a wide range of applications.

Features

1. Using linear coding, the palletizing speed is fast, up to 1200 bags/hour.

2. The use of servo coding mechanism can realize any stacking type stacking. It is suitable for the requirements of many bag types and various coding types. When changing the bag type and coding type, the bag dividing mechanism does not need any mechanical adjustment, just select the stacking type on the operation interface, which is convenient for variety change during production. The servo bag dividing mechanism operates smoothly, operates reliably, and will not impact the bag body, so as to protect the appearance of the bag body to the greatest extent.

3. Low power consumption, fast speed, beautiful stacking and saving operating costs.

4. Use heavy-pressure or vibrating leveling machine to squeeze or vibrate the bag body to make it smooth.

5. It can adapt to the multi-bag type, and the change speed is fast (the production variety change can be completed within 10 minutes).

|

Motor/Power |

380V 50/60HZ 13KW |

|

Applicable places |

Fertilizer, flour, rice, plastic bags, seeds, washing powder, cement, dry powder mortar, talcum powder and other bagged products. |

|

Applicable pallets |

L1000~1200*W1000~1200mm |

|

Palletizing speed |

500~1200 bags per hour |

|

Palletize height |

1300~1500mm (Special requirements can be customized) |

|

Applicable air source |

6~7KG |

|

Overall dimension |

Non-standard customization according to customer products |

Installation steps guidance