Dry mortar production line intelligent control system

Product Detail

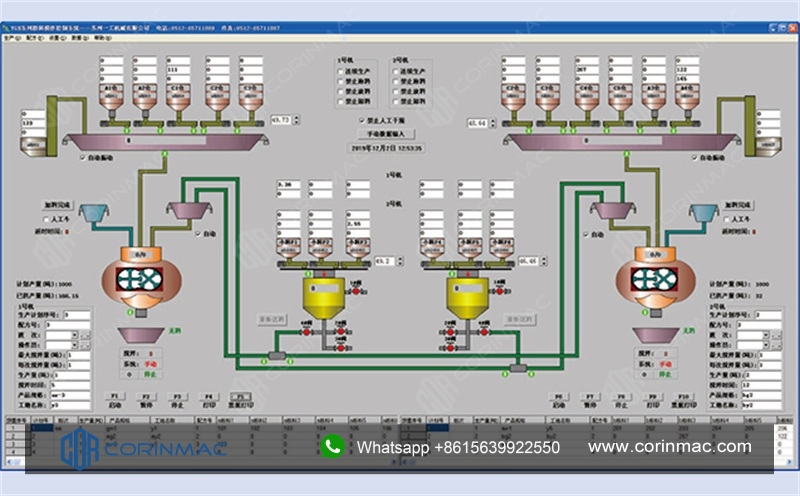

Control system

The automatic control system for the dry mixes production line is a three-level system.

The control system is designed according to customer requirements.

The computer control system realizes the automatic control and complete manual support of the whole process of measuring, unloading, conveying, mixing and discharging. Design the delivery note according to the user's requirements, can store 999 recipes and plan numbers, can be adjusted and modified at any time, dynamically simulate the entire production process, with computer self-diagnosis, alarm functions, automatic drop correction and compensation functions.

Normal level

Each equipment has its own separate control box. The system includes a control unit for weighing components and finished products, including sensors and converters, which can monitor and control the operation of the equipment according to a given algorithm, monitor the status of consumable components in the container, and have alarms and alarm instructions.

High level

The computer provides centralized remote control to input, edit and store formula and process parameters. The parameters of the production process are visualized. With the output of warning and alarm signals, the parameters of the production process can be recorded and archived, and the output of each raw material and the output of the finished product can be monitored.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

Customer feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.