High efficiency double shaft paddle mixer

Product Detail

Double shaft paddle mixer (Double shaft weightless mixer)

The technology of the double shaft paddle weightless mixer is mainly from Japan and South Korea, and it is more suitable for the mixing of materials with similar specific gravity. The double-shaft paddle mixer is equipped with double shaft counter rotating paddles. The paddles are overlapped and form a certain angle. The paddles rotate and throw the material into the space fluid layer, resulting in instant weightlessness and falling into each other's area., the material is mixed back and forth, forming a fluidized weightless zone and a rotating vortex in the middle. The material moves radially along the shaft, thus forming an all-round compound cycle and quickly achieving uniform mixing.

Product Details

Working principle

The twin-shaft paddle mixer is a horizontal twin-shaft paddle mixing equipment for forced mixing, designed for the preparation of all types of dry building mixtures with manual and automated control.

The twin-shaft paddle mixer consists of a horizontal body, drive mechanism, twin-shaft mixing blades. During operation, the twin-shaft relative reverse rotation leads the blades to different angles in order to rotate the material in axial and radial cycles, under the action of the double-shaft high-speed rotation, the material thrown up is in a state of zero gravity (i.e. does not have gravity) and descends, in the process of throwing up and lowering the material is mixed evenly. Cycle time: 3-5 min. (for complex mixtures up to 15 min.)

The mixing paddle is cast with alloy steel, which greatly prolongs the service life, and adopts an adjustable and detachable design, which greatly facilitates the use of customers.

1 to 1 customized service

We can do different program designs and configurations according to your requirements. We will provide each customer with customized production solutions to meet the requirements of different construction sites, workshops and production equipment layout.

Successful Project

We have many thematic sites in more than 40 countries around the world. Part of our installation sites are as follows:

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

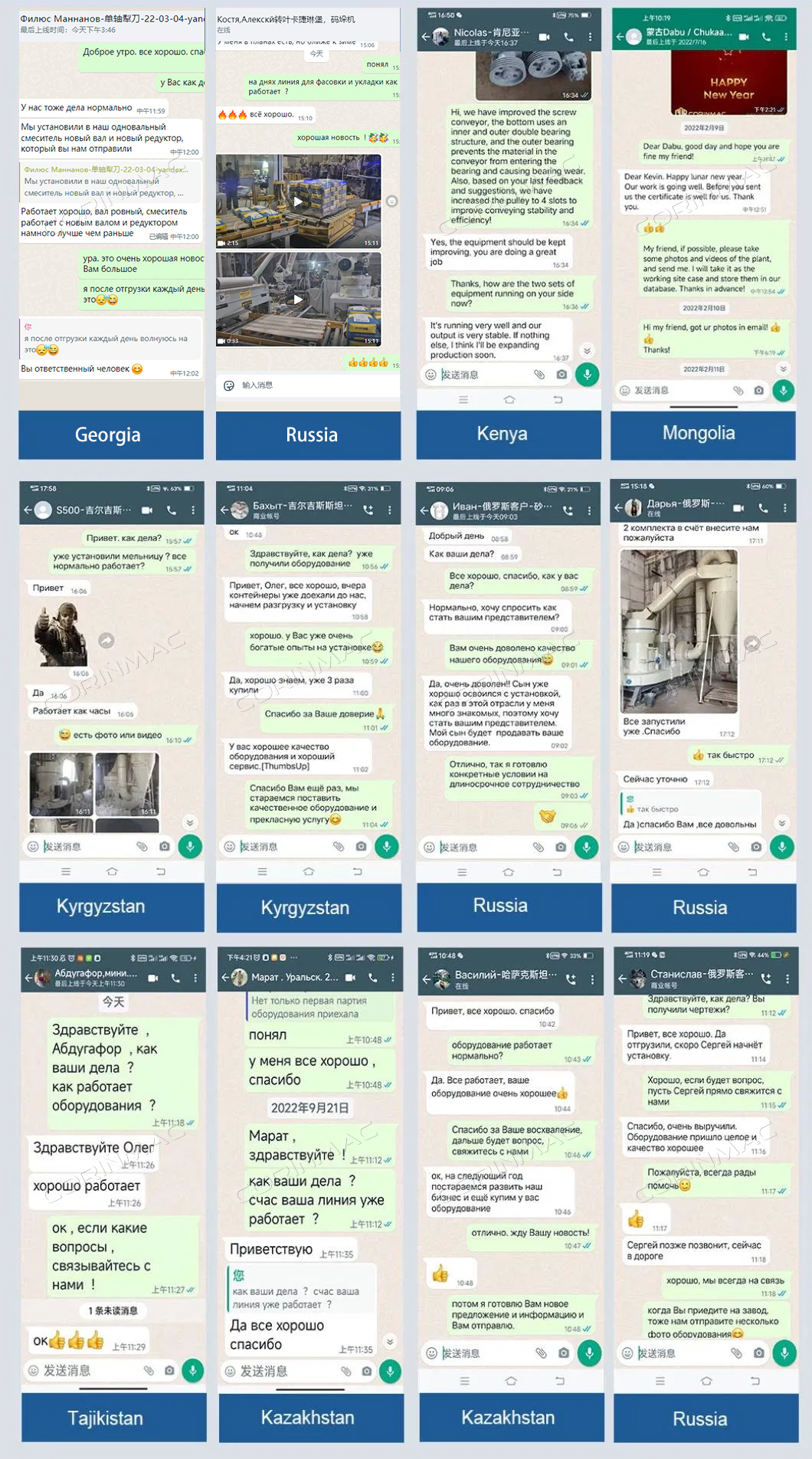

User Feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Drawing

Our products

Recommended products

Single Shaft Paddle Mixer

Single shaft paddle mixer is the latest and most advanced mixer for dry mortar. It uses hydraulic opening instead of pneumatic valve, which is more stable and reliable. It also has the function of secondary reinforcement locking and has extremely strong sealing performance to ensure that the material does not leak, even water does not leak. It is the latest and most stable mixer developed by our company. With the paddle structure, the mixing time is shortened and the efficiency is improved.

see moreSingle shaft plough share mixer

Features:

1. The plough share head has a wear-resistant coating, which has the characteristics of high wear resistance and long service life.

2. Fly cutters be installed on the wall of the mixer tank, which can quickly disperse the material and make the mixing more uniform and fast.

3. According to different material s and different mixing requirements, the mixing method of the plough share mixer can be regulated, such as mixing time, power, speed, etc., to fully ensure the mixing requirements.

4. High production efficiency and high mixing precision.

Reliable performance spiral ribbon mixer

The Spiral ribbon mixer is mainly composed of a main shaft, double-layer or multi-layer ribbon. The spiral ribbon is one outside and one inside, in opposite directions, pushes the material back and forth, and finally achieves the purpose of mixing, which is suitable for stirring light materials.

see more