High purification efficiency cyclone dust collector

Product Detail

Cyclone collector

The cyclone dust collector is designed for cleaning gases or liquids from suspended particles. The cleaning principle is inertial (using centrifugal force) and gravitational. Cyclone dust collectors constitute the most massive group among all types of dust collection equipment and are used in all industries.

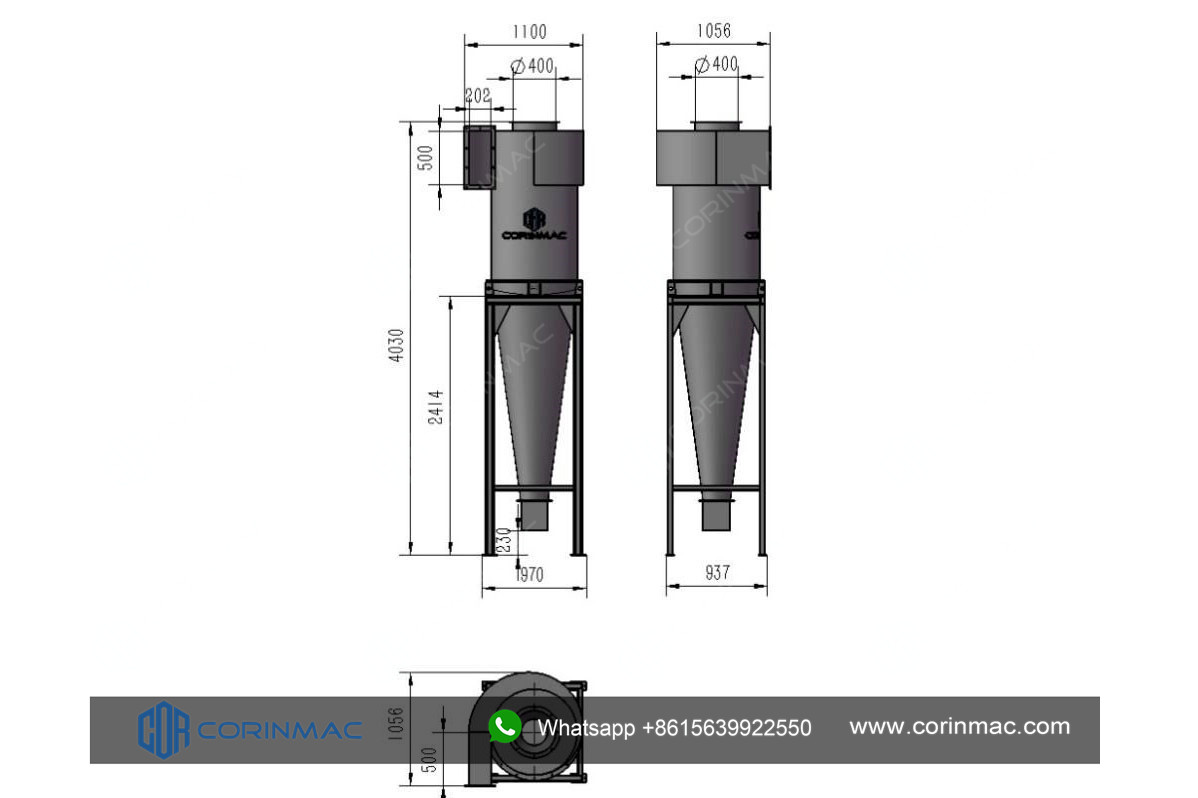

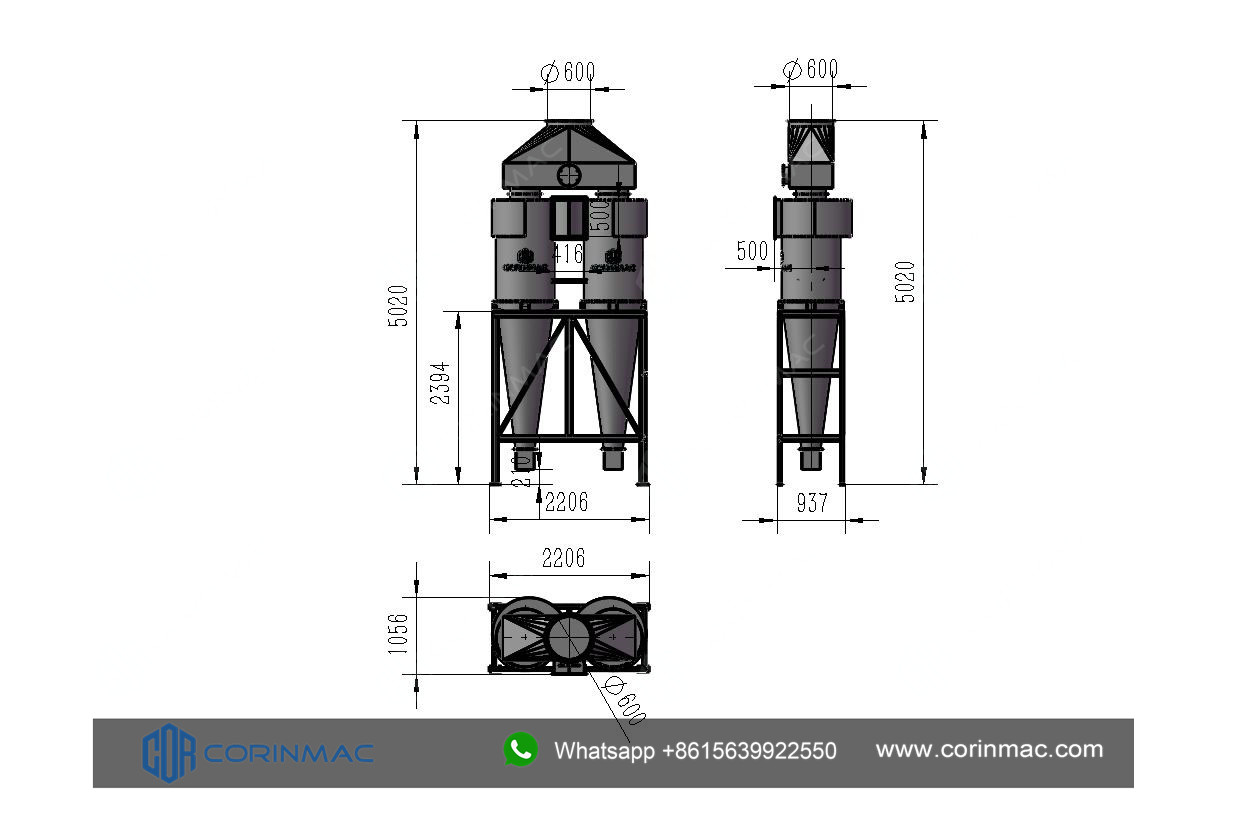

The cyclone dust collector is composed of an intake pipe, an exhaust pipe, a cylinder, a cone and an ash hopper.

Principle of operation

The principle of the counter-flow cyclone is as follows: a stream of dusty gas is introduced into the apparatus through the inlet pipe tangentially in the upper part. A rotating gas flow is formed in the apparatus, directed downward towards the conical part of the apparatus. Due to the inertial force (centrifugal force), dust particles are carried out of the stream and settle on the walls of the apparatus, then are captured by the secondary stream and enter the lower part, through the outlet into the dust collection bin. The dust-free gas stream then moves upwards and out of the cyclone through a coaxial exhaust pipe.

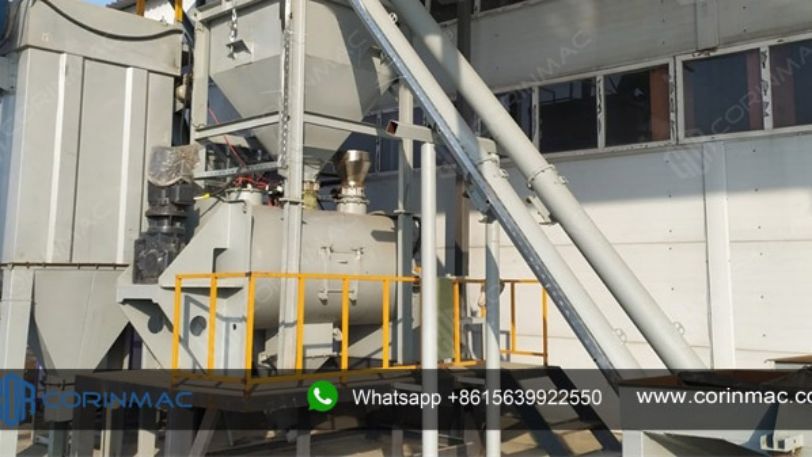

It is connected to the air outlet of the dryer end cover through a pipeline, and is also the first dust removal device for the hot flue gas inside the dryer. There are a variety of structures such as single cyclone and double cyclone group could be chosen.

Used in conjunction with the pulse dust collector, it can achieve a more ideal dust removal effect.

Installation steps guidance