Automatic ceramic tile adhesive mortar production line prices dry mortar mixer machine ceramic tile adhesive mortar have passed the strict quality testing of national authoritative institutions, reliable performance, stable quality, quality assurance, and enjoy a good reputation in the industry.Therefore,it can be extensively used for Dry Mortar Machines.

Model Number: CRH

Production Capacity: 999

Shipping: Express Sea freight · Land freight · Air freight

Customization: Customized logo (Min. Order: 1 pieces) , Customized packaging (Min. Order: 1 pieces) , Graphic customization (Min. Order: 1 pieces)

Products Description

According to customer requirements, we can design personalized production processes. The equipment of this production line includes: Dry sand production part, Material storage part, Material measuring system and additive measuring system, Mixing equipment and Packaging equipment.

Dry sand production part

In order to obtain dry sand that meets the production requirements, the raw wet sand must be dried and the moisture content should be less than 0.5%. The main production equipment used in the drying process is a three-pass dryer, which is newly developed for the drying of sand Dryer, high thermal efficiency, novel structure, compact, stable and efficient. After the sand is dried, it is sent to a classification screen by a belt conveyor. The dry sand is divided into several grains according to the process requirements and stored in the discharge bin.

Material storage part

The material storage part is composed of a number of round silos with different volumes, and the silos are equipped with maintenance ladders and guardrails. The top of the silo is equipped with a feeding port, an access port and a dust collector at the top of the silo. Each silo is also equipped with high and low level gauges, which helps the staff to understand the situation of the materials in the silo. The lower mouth of the silo is equipped with a valve, and various materials are conveyed to the weighing bin by a screw conveyor.

Material measuring system

The material measuring system consists of weighing bin, steel frame and sensor group.

The weighing bin is a closed bin body, the lower part is equipped with a discharge screw, and the upper part has a feeding port and a breathing system. Under the instruction of the control center, the materials are sequentially added to the weighing bin according to the set formula. After the measurement is completed, wait for the instructions to send the materials to the bucket elevator inlet of the next link. The entire batching process is controlled by the centralized control cabinet PLC. Control, high degree of automation, small error and high production efficiency.

Additive measuring system

The additive metering system consists of a bucket, a feeding screw and an additive measuring scale. The whole set of components is made of stainless steel, and the contact surface with the additive is finished to avoid the adhesive and residue. Additive measuring scale uses a high-precision weighing system to achieve accurate dosing with an error range of ± 0.1%

Mixing main machine

The mixing main machine is generally a double-shaft non-gravity mixer or a single-shaft coulter mixer, which can be targeted for selection according to the material. According to the program set by the PLC, the materials begin to mix after entering the main machine, and the mixing is completed after 3-5 minutes. The control program issues an instruction to open the mixer's discharge door to discharge. In addition, in the process of material mixing, the next batch of materials has been finished.

Packaging Equipment

The production line is equipped with air-blown or air-floating packaging machines, and the number of packaging machines is determined according to the required output. In addition, the entire production line is equipped with a dust removal system to reduce dust and improve the working environment; the air supply system is an air compressor with a displacement of not less than 0.6m³ / min and a matching air storage tank.

Features At A Glance

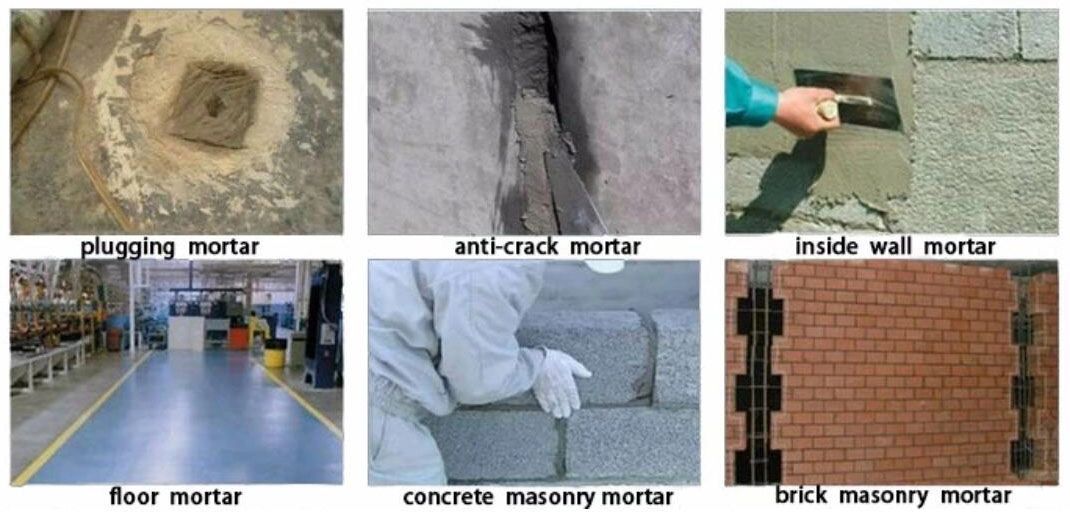

Applicaton of Dry Mix Powder Mortar Production Line

Product Configuration