Main material weighing equipment

Product Detail

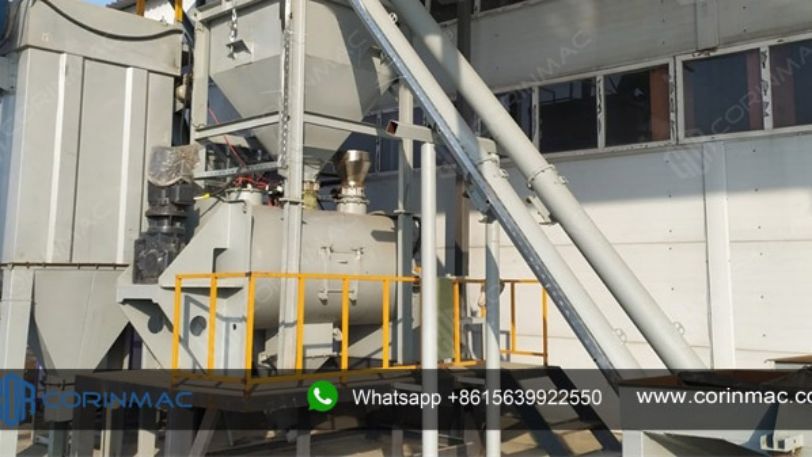

Introduction

The weighing hopper consists of hopper, steel frame, and load cell (the lower part of the weighing hopper is equipped with a discharge screw conveyor). The weighing hopper is widely used in various dry mortar production lines to weigh ingredients such as cement, sand, fly ash, light calcium, and heavy calcium. It has the advantages of fast batching speed, high measurement accuracy, strong versatility, and could handle various bulk materials.

Working principle

The weighing hopper is a closed hopper, the lower part is equipped with a discharge screw conveyor, and the upper part has a feeding port and a breathing system. Under the instruction of the control center, the materials are sequentially added to the weighing hopper according to the set recipe. After the weighing is completed, wait for the instructions to send the materials to the bucket elevator inlet for the next process. The entire batching process is controlled by PLC in a centralized control cabinet, with high degree of automation, small error and high production efficiency.

Installation steps guidance