Cost-effective and small footprint column palletizer

Product Detail

Introduction

Column palletizer can also be called Rotary palletizer or Coordinate palletizer, it is the most concise and compact type of palletizer. The Column Palletizer can handle bags containing stable, aerated or powdery products, permitting partial overlapping of the bags in the layer along both the top and sides, offering flexible format changes. Its extreme simplicity makes it possible to palletise even on pallets sitting directly on the floor.

The machine features a sturdy rotating column with a rigid horizontal arm connected to it that can slide vertically along the column. The horizontal arm has a bag pick-up gripper mounted on it that slides along it, rotating around its vertical axis.The machine takes the bags one at a time from the roller conveyor on which they arrive and places them at the point assigned by the program.The horizontal arm descends to the necessary height so that the gripper can pick up the bags from the bag infeed roller conveyor and then it ascends to permit free rotation of the main column. The gripper traverses along the arm and rotates around the main column to place the bag in the position assigned by the programmed palletising pattern.

The arm is positioned at the required height and the gripper opens to place the bag on the pallet being formed. At this point, the machine returns to the starting point and is ready for a new cycle.

The special construction solution gives the column palletizer unique features:

Possibility of palletizing from several pickup points, in order to handle bags from different bagging lines in one or more palletizing points.

Possibility of palletizing on pallets set directly on the floor.

Very compact size

The machine features a PLC-controlled operating system.

Through special programs, the machine can perform virtually any type of palletizing program.

The format and program changes are carried out automatically and very quickly.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

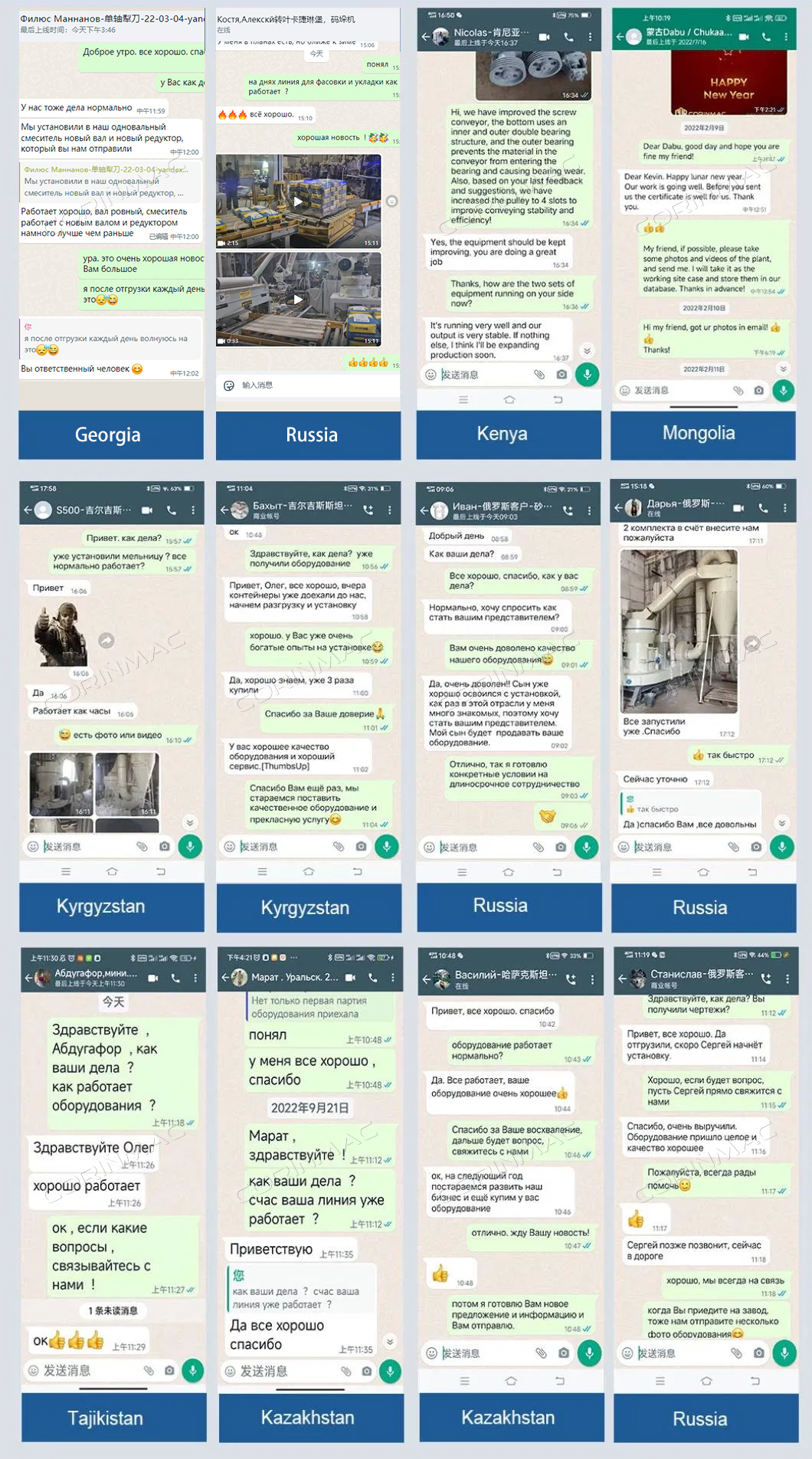

User Feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Installation steps guidance