Stable operation and large conveying capacity bucket elevator

Product Detail

Bucket elevator

The bucket elevator is designed for continuous vertical transportation of bulk materials such as sand, gravel, crushed stone, peat, slag, coal, etc. in the production of building materials, at chemical, metallurgical, machine-building enterprises, at coal preparation plants and other industries. Elevators are used only for lifting loads from the starting point to the final point, without the possibility of intermediate loading and unloading.

Bucket elevators (bucket elevators) consist of a traction body with buckets rigidly attached to it, a drive and tensioning device, loading and unloading shoes with branch pipes, and a casing. The drive is carried out using a reliable geared motor. The elevator can be designed with a left or right drive (located on the side of the loading pipe). The elevator (bucket elevator) design provides for a brake or stop to prevent spontaneous movement of the working body in the opposite direction.

Choose different forms according to the different materials to be lifted

Belt + Plastic Bucket

Belt + Steel Bucket

Bucket elevator appearance

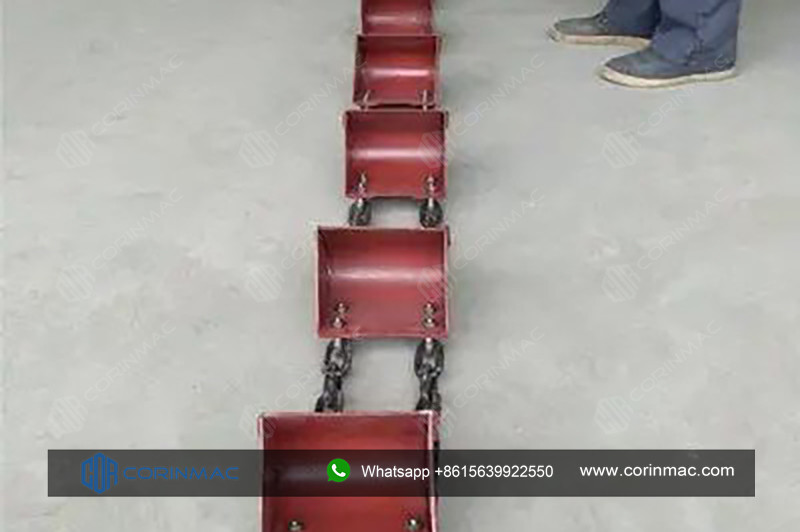

Chain type

Plate chain bucket elevator

Delivery photos

Successful Project

We have many thematic sites in more than 40 countries around the world. Part of our installation sites are as follows:

Technical Parameters of Chain Bucket Elevator

|

Model |

Capacity(t/h) |

Bucket |

Speed(m/s) |

Lifting height(m) |

Power(kw) |

Max feeding size(mm) |

|

|

Volume(L) |

Distance(mm) |

||||||

|

TH160 |

21-30 |

1.9-2.6 |

270 |

0.93 |

3-24 |

3-11 |

20 |

|

TH200 |

33-50 |

2.9-4.1 |

270 |

0.93 |

3-24 |

4-15 |

25 |

|

TH250 |

45-70 |

4.6-6.5 |

336 |

1.04 |

3-24 |

5,5-22 |

30 |

|

TH315 |

74-100 |

7.4-10 |

378 |

1.04 |

5-24 |

7,5-30 |

45 |

|

TH400 |

120-160 |

12-16 |

420 |

1.17 |

5-24 |

11-37 |

55 |

|

TH500 |

160-210 |

19-25 |

480 |

1.17 |

5-24 |

15-45 |

65 |

|

TH630 |

250-350 |

29-40 |

546 |

1.32 |

5-24 |

22-75 |

75 |

Technical parameters of plate chain bucket elevator

|

Model |

Lifting capacity(m³/h) |

Material granularity can reach(mm) |

Bulk density of material(t/m³) |

Reachable lifting height(m) |

Power range(Kw) |

Bucket speed(m/s) |

|

NE15 |

10-15 |

40 |

0.6-2.0 |

35 |

1.5-4.0 |

0.5 |

|

NE30 |

18.5-31 |

55 |

0.6-2.0 |

50 |

1.5-11 |

0.5 |

|

NE50 |

35-60 |

60 |

0.6-2.0 |

45 |

1.5-18.5 |

0.5 |

|

NE100 |

75-110 |

70 |

0.6-2.0 |

45 |

5.5-30 |

0.5 |

|

NE150 |

112-165 |

90 |

0.6-2.0 |

45 |

5.5-45 |

0.5 |

|

NE200 |

170-220 |

100 |

0.6-1.8 |

40 |

7.5-55 |

0.5 |

|

NE300 |

230-340 |

125 |

0.6-1.8 |

40 |

11-75 |

0.5 |

|

NE400 |

340-450 |

130 |

0.8-1.8 |

30 |

18.5-90 |

0.5 |

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

Customer feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Installation steps guidance

Drawing

Our products

Recommended products

Screw conveyor with unique sealing technology

Features:

1. The external bearing is adopted to prevent dust from entering and prolong the service life.

2. High quality reducer, stable and reliable.

see moreDurable and smooth-running belt feeder

Features:

The belt feeder is equipped with a variable frequency speed regulating motor, and the feeding speed can be adjusted arbitrarily to achieve the best drying effect ore other requirement.

It adopts skirt conveyor belt to prevent material leakage.

see more